In this article, I will share with you how I managed to make a double bed. Finally, I finished repairs in my bedroom, and it's time for the main attribute of this room - the bed. I started looking for the Bed options on the Internet, which I would like to purchase. I got an interesting design of the bed, but I did not find stores where you could buy such a bed.

It was an exclusive option that is performed under the order. I didn't even learn how much the manufacture of such a bed would cost, because I already know that it is expensive. If the usual bed with primitive design stands in the store from 15,000 - 20,000 rubles. The option that I wanted to undergo a minimum of 30,000 rubles. Therefore, I had an idea to make a bed itself, which just fit into the dimensions of the room.

Size of the future bed

I had a 2x1.60 meter mattress. It was from this that I was repelled when I counted the sizes of the bed. Room width 2 meters. It turns out if the width of the mattress is 1.60 meters from this width, then I remained 40 cm for lateral shelves. Consequently, the shelves from both sides by width will be 20 cm.Materials

Calculating all the sizes of the bed, and depicting it on the paper, I calculated about how much the material is required. I had to buy:

- 2 laminated chipboard sheet;

- 2 bruck 200x15x5 cm;

- 8 bars 200x5x3 cm;

- 1 sheet DVP with laminated side of white color;

- Ready metal frame with lamellas, just under the size of my mattress 2x1.60 m;

- Gas mechanism for opening a frame;

- Fittings for the shelves: Spring Springs, Cutting Handles;

- Edge for chipboard;

- As well as self-tapping screws and conferences.

Making a double bed

So, for a start, I took the 200x15x5 cm timber, and cut two parts from it with a length of 90 cm.

You need two such elements. Since the width of the bar is 15 cm, and adding 1.5 cm chipboard to this width on both sides, then the width of the sidewalls is 18 cm.

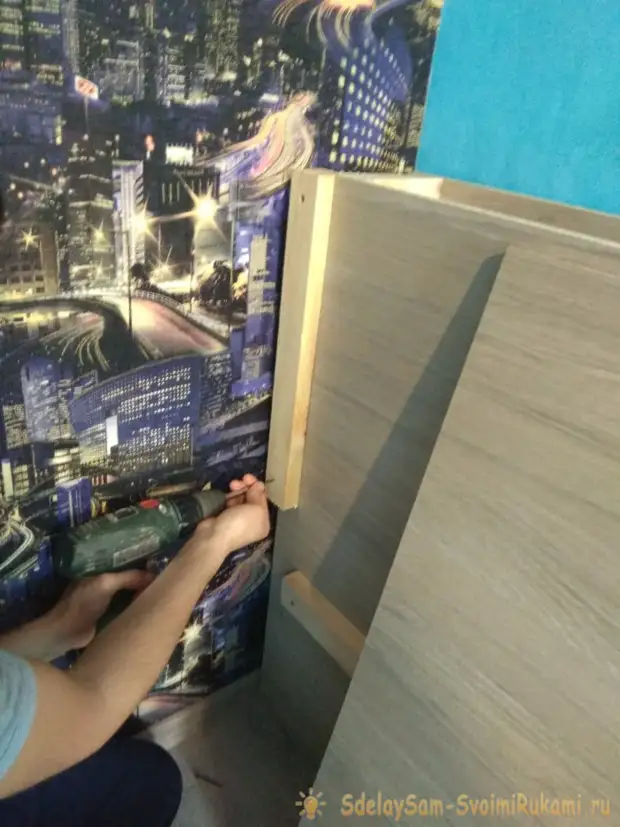

After that, you can proceed to the manufacture of the back of the bed. It is necessary to collect the framework to which the DSP sheet 165x90 cm will be attached. I attached a 5x3 cm timber from two sides, and I attached a chipboard to the apparmatics.

From the front of the bed, it is also necessary to attach a sheet of chipboard of the size of 200x40 cm.

After that, I took up a metal frame. As a rule, it should fall on wooden bars, which should be throughout the plane of the bed so that the load is distributed evenly. Therefore, it is necessary to attach the timber at height from the floor 30 cm to the rear, front and side parts. On the sides of the bar should not be along the entire length, but to take place for fastening the mechanism somewhere 40 cm.

Next, I put a metal frame to make sure that the dimensions are accurate, and then began to fix the mechanism.

First you need to unscrew the gas tube with the key, and attach the mechanism without it.

Then I made an inner partition, dividing the inner department into two parts. To do this, I used a particle of chipboard of the size of 200x30 cm, and it attached a bar on it from above to the screws. In terms of side bars.

Thus, the frame lies evenly and on the side bars, and on the bar which in the middle. In the inside, where bed linen will be folded, on the floor I put the fiberboard with a laminated part of white. I was cut out by the jigsaw exactly in the size of each compartment, and just put it on the floor.

Then I additionally brought some fastenings with metal corners. Especially in those places where the load will be.

After that, I evenly measured the label on the opening covers, in order to cut holes for mortise knobs. Mount the handles from the back of the cover with bolts that are included in the kit.

The final stage of my work was the cloak of the edge to the prominent parties of the chipboard. This service could be ordered where I ordered cutting chipboard. However, in this case I had to wait even longer, and I already wanted to move to a new bedroom. In addition, this service seemed to me too expensive. Adhesive adhesive is easily performed. To do this, I bought an approximate amount of edge that I need to make prominent places. I cut off the size of the edge for the desired fragment, and, wipeing the heated iron, spent several times on the edge. Then the construction knife cut the excess from the edge, which went beyond the thickness of the chipboard. Also I bought special stickers, under the tone of the chipboard, which are designed to close the hats of self-tapping and conformimates so that they do not get into the eyes.

This work seemed to me difficult at the beginning, but in fact, everything was very simple. For the manufacture of bed I took 3 days. The bed came out very comfortable and spacious. I found many options to apply the opening bones on the sides. Perhaps this option of the bed will inspire you to make a similar design, which will undoubtedly perfectly fit into the interior of any bedroom.

A source