The epoxy resin table is the crown of the modern furniture industry. Already that year, similar tables are a subject of luxury capable of truly to decorate any interior. The editorial office of 365News has worked in this direction by collecting detailed information on what is the table from epoxy, which species happens, and how you can make it yourself from the girlfriend.

Sea depths in miniature

All over and against epoxy resin tables

Looking at this or that construction material, always asked how good it is, and whether his advantages are really outweigh all the disadvantages. Positive qualities of epoxy resin are as follows:

- increased strength to mechanical damage and moisture resistance;

- long service life;

- ease of care;

- the possibility of incarnation of various design solutions;

- Availability for independent work - only a bit of snacks and knowledge of a certain technology are required;

- Low cost - epoxy resin for pouring table tops relatively inexpensive, if we consider it in one row with concrete, solid wood or stone. And according to quality characteristics, they do not infer at least.

Epoxy resin is not ideal in all sense material. Products from it have disadvantages:

- Sensitivity to the processing by any abrasive compositions - there are unpleasant scratches;

- Incorrectly cooked resin may subsequently disrupt the quality of the final product;

- Some types of epoxy resins are not a rack to ultraviolet and eventually begin to give yellow;

- Selection of toxins. They begin to stand out into the atmosphere only with long-term contact with high temperatures, so they are afraid to put a hot dish or a cup of coffee onto the epoxy table. But to solder on such countertops or burn them is extremely recommended.

Note! Epoxy resin is not ignited and does not melt even when opening with open fire. But it poison the air is pretty.

Types of epoxy resin tables and their features

Looking close to the purchase of a table of epoxy resin and considering prices, you come to the conclusion: in fact, they are all alike. And it is possible to divide such products into several groups.Table tops from epoxy resin without reference surface

An epoxy countertop is a separately manufactured element, which can be both part of the table and the working surface in the kitchen headset.

You can just just buy a tabletop from epoxy resin and install it on your reference basis. It remains only to choose the right size and favorable design.

Countertops from epoxy resin, wood and other supporting elements

Epoxy resin countertops are also made on any reference structures. Most often it is the base of timber, metal, plastic or solid wood. Someone manages to adapt the foundations from old stools and chairs as a support for tabletops.

As a rule, the masters for greater reliability make support elements and a tabletop in a single whole, pouring epoxy directly to them in the pre-installed formwork.

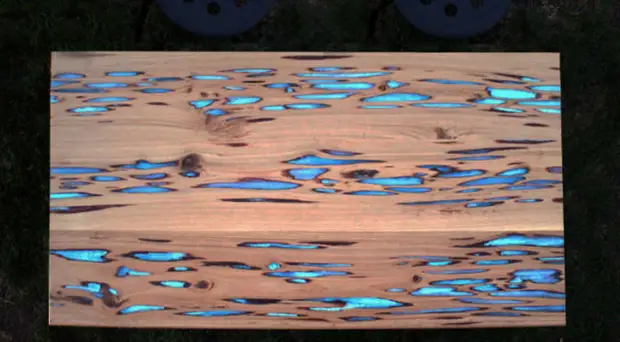

Wooden table with additional filling and epoxy resin

Tables made of wooden elements and epoxy today are incredible popular. At the same time, in many design models there is nothing extraordinary - just beautiful (sometimes the ugly beautiful) rusties, whole wooden arrays, poured by a resin. For example, like tables made of wood and epoxy resin in the photo below.

Other decoration elements can be added to such interesting tables: phosphorus for night glow, marine pebbles, glass, sparkles, seashells - only fantasy creators will be restricted here.

Note! Easy items must be adopted to base, otherwise they will pop up when pouring!

Table of Sleba and Epoxy Resin - Style and Incredible Beauty

Production of tables from wood, or rather from the slab and epoxy resin - the trend of the season. First of all, because Slab is a drink of wood - has a unique texture, shape and drawing. It's like fingerprints: there are no identical sleep, each in its own way is unique. Therefore, products from them are very highly appreciated as aesthetes and manufacturers.

Make an independently such a table or countertop is not so difficult. It is only necessary to choose the right SLEB and pour into a transparent or painted epoxy resin.

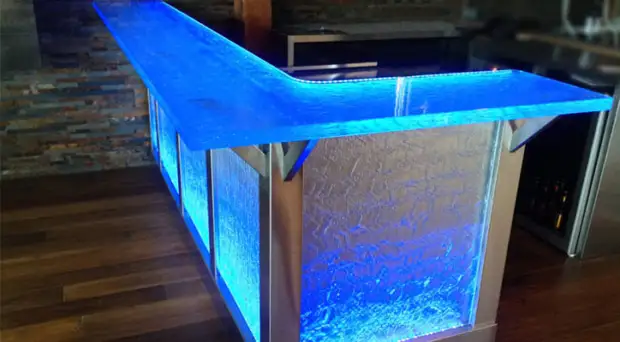

River-river based on epoxy resin

Special attention deserves a table of liquid glass and wood, the so-called "river". In fact, it is two slabs, between which the epoxide of a blue color is flooded, perfectly imitating the water of a clean river. Some models also have a glass that completely covers the entire surface. Here, as they say, taste and color.

Some masters are added to phosphorus epoxy, which turns such a table in a kind of night light. Parties with the so-called multistage slab, giving mysteriousness and depths, are particularly interesting. You can also buy tables with fish, reefs and whole marine colonies inside the epoxy filler. But such products are rare. It's easier to make such beauty.

If it is decided to buy a table from a tree and epoxy resin: focus on price review and basic quality criteria

Eh, love - so the queen, steal - so Million, buy a table - so from epoxy! If you are a supporter of such views, then pay attention to the small nuances when choosing such furniture, then not to complain about leaving masters.

Immediately it should be noted that any epoxy furniture is handmade. Therefore, a great risk of marriage. Still, the human factor in the manufacture of such furniture plays a crucial role. What should be a high-quality app of epoxy resin:

- No chips, cracks, scuffs and other defects are even the smallest. Do not hesitate and look under the worktop;

- We look at the thickness of the table top - it should be the same on all sides. No slopes and distortions;

- Carefully look at the epoxy - no bubbles, as if the seller nor explained that it is all so necessary for greater decorativeness. Air bubbles in frozen epoxy resin - a sign of incorrect technology of working with it, this sharply reduces the quality of the final product;

- You need glass on the surface or not - to solve you. Keep in mind that the glass on the table top is the most short-lived element, in contrast to epoxy resin and wood.

As already noted, epoxy resin tables are handmade. So it will cost such an exclusive a lot. For example, small coffee tables can be purchased in the price range from 11,000 to 30,000 rubles - or more expensive. Dining and office tables stand from 50,000 rubles - it all depends on the model and rates of the wizard. Present prices are relevant for September 2018.

Epoxy Table Production Technology

For those who have hands to make their own to independently make a table from epoxy resin, tell me how to do it correctly and inexpensive.How to choose an epoxy resin for the table - reviews and recommendations

Revising a bunch of video about how easy and easy to work with epoxy resin, so I want to make a tabletop with your own hands. That's just what? A beginner in this area the choice of epoxy can put in a dead end. What kinds and marks do not exist!

"ED-20" - One of the popular and inexpensive resins used both for filling furniture and for decorations. Popularity has deserved its low cost. This plus is equalized by minus - yellow products. Of course, the yellowness is not immediately acquired, but over time, and only if the flooded resin fell by direct sunlight. It is also characterized by increased drig, which is not good when working with a resin, especially for beginners. To solve such problems, you can purchase a plasticizer for epoxy resin - for example, DBF EPOXYMAX.

"Art Eco" - crystal clear and transparent resin, designed to work with small thickness products, including with countertops. When working, it is recommended to use hardeners. Of the negative points, there is a yellowness on transparent products under direct sunlight. This disadvantage is eliminated by the use of dyes, which can also be purchased from this manufacturer.

«QTP-1130» - the ideal option for pouring tables and countertops, provided that the thickness of the epoxy layer will not be more than 3 mm. It is easy to work with it - no additional plasticizers and hardeners do not need. It has self-leveling, which is very convenient for beginners.

"EP-SM-PRO" - inexpensive composite epoxy resin. It is good for work with a tree. It is uniformly mixed, the bubbles practically does not appear, the transparency is good, freezes to the end and relatively quickly. It has a liquid consistency, which must be taken into account when forming formwork - can leak even through small slots.

"PEO-610KE", "EPOXIASTER 2.0", "EPOXACAST 690". Products from these resins are not afraid of ultraviolet and possess crystal transparency. Working with similar compositions is nice - not viscous, quickly and fully frozen, have a small tendency to self-leveling.

"ArtLine Crystal Epoxy" - Suitable for working with jewelry, and for fills there is a small thickness. Liquid, transparent, well aligned with a spatula. Products are obtained transparent and without distortion. Bubbles are practically not formed and easily removed. It has a not very good reaction with some types of dried flowers. If you work with such a filling, determine in advance whether there is a conflict between epoxy and herbarium. Feedback on the use of similar epoxy resin is lower.

"MG-EPOX-STRONG" - Epoxy resin universal destination, more recommended for filling precisely countertops and tables. It has excellent quality and operational characteristics. It is nice to work with it. A large thickness is suitable for filling with various fillers - from weightless phosphorus to heavy pebbles and coins. In this case, no yellowness, high mechanical strength and inconsistency with the effects of high temperatures.

How to calculate the materials necessary for the manufacture of the head of the epoxy?

- A drawing is done, according to which the supporting structure, formwork and fillers are being worked out in detail, if any.

- Depending on the type of epoxy resin, a consistency is selected and the corresponding breeding proportions for further work.

Note! Some formulations are not bred, you can work almost immediately - and this leads to the rise in the cost of the final product.

Production of supporting design

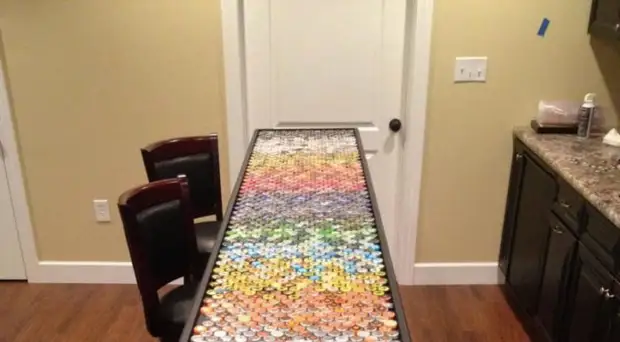

In our small master class, consider how you can make a simple coffee table from accessible to each material, having received designer furniture as a result.

| Illustration | Description of action |

| We will need: two circles of wood, plastic pipe, which will perform the role of rack, glue, better on epoxy, thick furniture border, epoxy resin itself and filler - beer covers. In our master class, the purchased design of brates for cats is used. |

| We collect the reference design. Carefully degrease the surface and soil. |

Preparation of formwork and filling

We make the first fitting - lay out the filler around the perimeter of the table top to understand what thickness to glue the furniture tape.

| Illustration | Description of action |

| It all depends on the thickness of the decor, it is necessary that it can be drifting in an epoxy at least half. |

| Gently glue the tape on the worktop, as it is not just a formwork, but part of our table. |

| We post the decor on the table top just as it will look in the final edition. I remember the location and remove everything. |

| We take glue and apply on the back side of the lid. |

| We glue all the covers to the tabletop. We do it carefully, as each subtext of the adhesive will be visible on the transparent surface. |

Preparation of epoxy

How to prepare an epoxy resin - prompts the instruction on the package. In our case, we used Epoxy Master 2.0. This is a two-component composition. If you need to add colors, add the kel only to the "A" component before getting the desired shade. Mix thoroughly.Note! So that the pigment is better dissolved, put it for some time to the battery or on a water bath, the temperature of which will not be more than 40 ° C, but not less than 30 ° C. If the resin is overheated, it can be thrown out.

Add a component "b" - hardener, in a 100: 35 ratio, as indicated in the instructions. Mix thoroughly. If suddenly bubbles were formed, then the resin can be heated with a hairdryer, while stirring until they disappear. The shelf life of the resulting solution is approximately 7 hours.

How to fill with an epoxy resin countertop

The most important stage of work is pouring resin. The most important thing here is to accurately follow the instructions. The diluted composition gently poured from the middle. Under the weight of his gravity, he will start align. If the table top is large, then expand the fill radius. When the entire volume to the edges of the formwork will be filled, as accurately smash the epoxy resin smoking. If the surface has not been lifted with a formwork thickness - most accurately add missing grams and align again. Leave to stick our worktop to the end.

In principle, we received the final product that can be used in your pleasure. Using "Epoxy Master 2.0" does not imply the final grinding of the product. But if she is still needed, we recommend to take a look at the video, how do the epoxy resin table do it yourself.

Recommendations for Epoxy Resin

Epoxy resin, though harmless in the frozen state, but the working can cause skin irritation and mucous membranes. Therefore, we work with it only in good quality rubber gloves - without the risk of sudden shash. Such gloves will need to be thrown immediately after a single fill session.

We also do not forget about glasses, respirator. The latter can not wear - everything depends on the type of epoxy used. Carefully read the instructions before buying. We also close all parts of the body of clothing - no open skin. We definitely work with epoxy only in well-ventilated premises, where you and your households do not sleep and are not in a row more than 5 hours. If the time of frozen resin is more than 3 days, it is necessary to acquire dust and organic filters.

Note! Epoxy resin in liquid state is easily removed from any surface with warm water. Not a wet rag, but directly water.

As we have managed to make sure, it is really quite simple to work with epoxy resin. It is only necessary to choose the proper composition, both according to the characteristics and in terms of the difficulty of working with it. And there - forward, to the creation of masterpieces!