We clean and combine the wires.

So, it will be necessary for work in mandatory solder, flux, soldering iron. Instead of flux, you can use the alcohol solution of rosin. It will take a mounting knife, and even better - stripper. Also will be needed fine copper wire. When all this is ready, you can take a job and be accepted for the preparation of wires and soldering.

We carry out the winding wire.

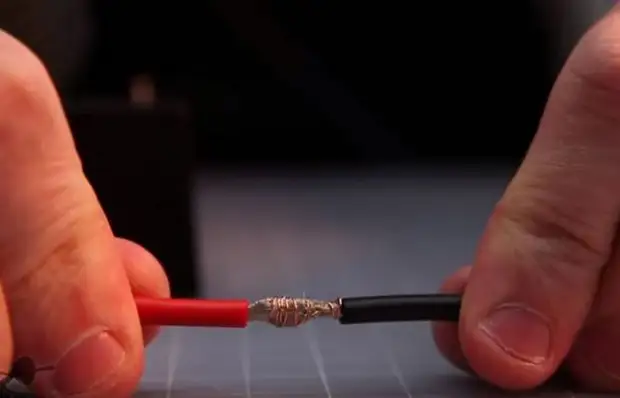

The process of compounds from cleaning isolation begins. In this case, a knife or stripper will help. It will be enough to open only 1 cm on each of the connected wires. When it is ready, copper veins on both wires should be fluffed, after which it is bumping into the ends of the ends. As a result of this connection, both will have to break the fan. As soon as this happens, they will have to clip their fingers. Very neat and nele.

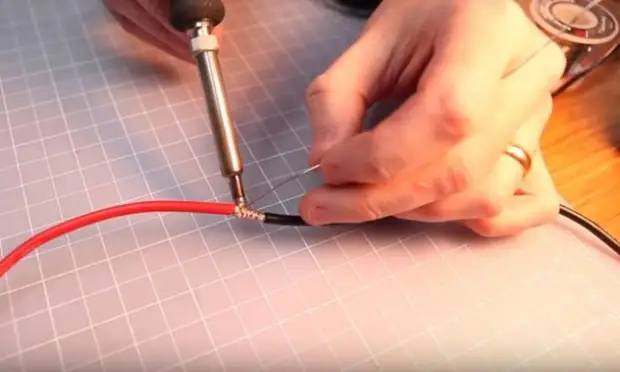

We start to solder. /

At the place of splicing, the veins are wrapped with a thin wire. It is very important that the wire used is a slightly thicker of a separate "hairs" in the cross section of the wires. The winding is made with an average frequency. Please note that if you try to put the turn to the twist, the connection will turn out to be more durable, reliable and neat. While winding the wire should be stretched. When the bandage is ready, it should be finally tightened. To do this, wire connections are neatly stretched.

Complete work.

Note : According to the final tightening of the bandage from the copper wire, the design of two wires should succeed in no less durable than the usual wire.

It remains very little. Golden veins at the splicing site are wicked by flux. Then, with the help of the soldering iron, veins and bandage are heated. It is applied to the hot plots. A soldering iron at the same time we gradually shift to still immentable places. It is necessary to make the molten tin penetrated under the bandage and closed all the existing emptiness (or at least most).