The best tool for cutting metal structures of different types and profile remains Bulgarian. Quite simple and at the same time a very effective tool today is subject to many owners. Despite this, as a sad practice shows, citizens when working with a grinder admit a sufficiently large number of errors. Some of them are fraught with the injury and dismissal of the instrument.

1. Installing an enlarged disk

The disk must be native.

Installing the larger disk on the grinder cannot be at least because it will have to remove the protective casing, making the tool frankly unsafe for the operator itself. In addition, the size of the disk must be compatible with the number of revolutions performed. For each disk and tool there are its contractual indicators. At best, incompatibility leads to loss of performance. In the worst case, the disc can simply burst and damage the operator (it is especially dangerous in the conditions of removable protective casing).

2. Using "non-rigging" disks

Must be sized.

For the grinder, it is strongly recommended to purchase only "native" discs, which are created by the manufacturer of a particular tool. Moreover, it is not necessary to save on the equipment and purchase cheap discs from little-known manufacturers. This is important, if I don't want the surgeon to hatch metal fragments from hand and body.

3. Work without protective casing

Must be a casing. |

Indirectly, this issue was already mentioned in the first paragraph, but it should be given to individual attention. In no case cannot work with a grinder with which there is no (for some reason) protective casing. If the disk burst during operation, it will split by fragments in all directions. Actually, it is for this that the casing is installed on the tool, which will have to take the main blow to itself in case of trouble.

Important : In addition, while working with a grinder is strongly recommended to use the provided means of individual protection - glasses or mask, as well as headphones. Recall that the noise of the grinder during operation is 90-100 dB. The permissible level of noise when working with the power tool is 80 dB.

4. Incorrect cutting direction and poorly tightened fasteners

You need to take a sure corner.

Remember that the fastening nut corresponds to the right and high-quality fixation of the work disk. If the disc is poorly tightened, it is fraught with its breaking during operation. Cut disk can trust or even worse - explode. Deviations should not exceed 3 mm inclusive! Before starting work, it is better to check the quality of fixation.

Already during work, very often sparks begin to fly per person. Many workers at the same time decide to turn the tool so that the sparks flew by. This is a malicious violation of the rules of operation of the instrument and safety instrument. In order to protect against sparks, you must not change the direction of the cut, but simply use a special robe.

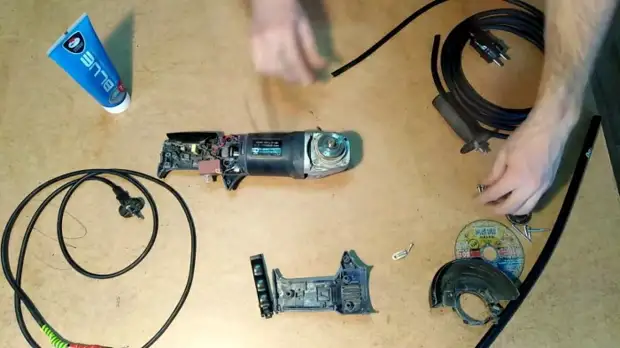

5. Faulty cable

Check the cable.

Finally, it is always necessary to check the health of the tool cable before the start of the "full-scale" work. Very often, people are injured in an attempt to fix the cable, erroneously believing that he turned off. In reality, the wire simply leaves. As a result - an unexpectedly earned tool and injury.