During the treatment of wood, many not very experienced masters and owners appear a variety of difficulties associated with one question. Like any other thing, the joinery craft has a huge number of secrets and subtleties. Therefore, now we are talking about the advice, which are often given by real masters of novice.

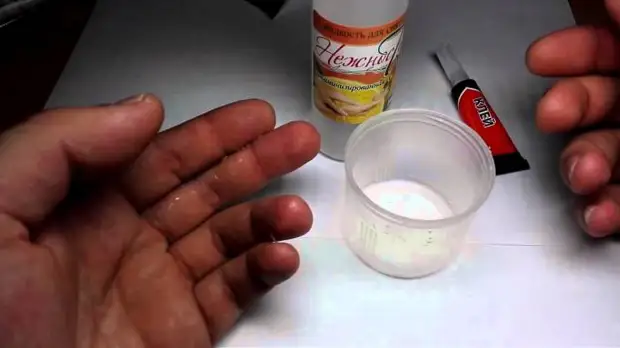

1. Putty for materials

You can do it yourself.

Pick up the putty to the color of the tree is possible, it is extremely difficult. In order not to play "Guessing", it is best to cook it yourself. To do this, the sawdust should be collected during cutting materials. Putclotka from sawdust by adding PVA glue, gradually mixing and bringing to the state of "Cashitz".

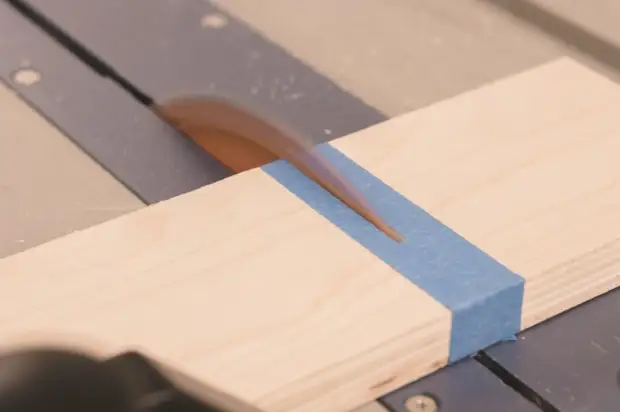

2. Avoid chips on plywood

Glue scotch.

This problem appears in the absolute majority of cases when working with the material mentioned. At the same time, absolutely no matter exactly the tools were used. In order to avoid chipping, the paint tape should be pasted into the place of cut. He will protect the material. Of course, the scotch still needs to make markup.

3. Remove the screws with smoothed edges

Rubber will help.

The hardware is "slid" most often with the improper use of the instrument or in the case of the use of goods from low-quality materials. In most situations, it is not so difficult to unscrew such a self-sufficiency at all, as it may seem at first glance. It is often enough to simply put between a hardware and a screwdriver (screwdriver) a piece of rubber.

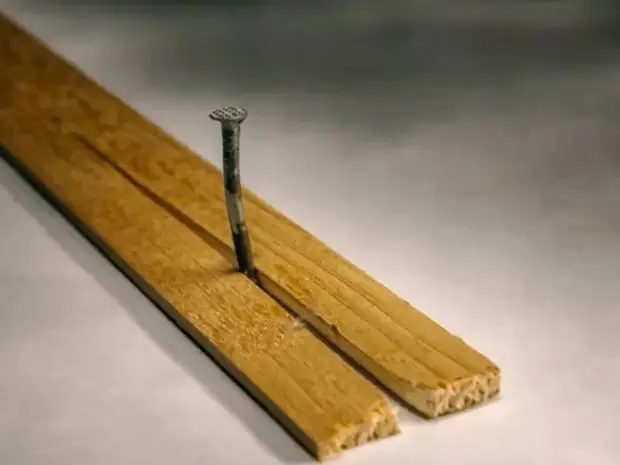

4. Score a nail into a thin rail

To score a nail into the rail is not difficult.

In order for a thin rail to not cracked the nail during clogging into it, it will be enough to join the hammer used a little. Now he will push the fiber of the tree, and not tear them. You can also try to overlay a hole of a smaller diameter.

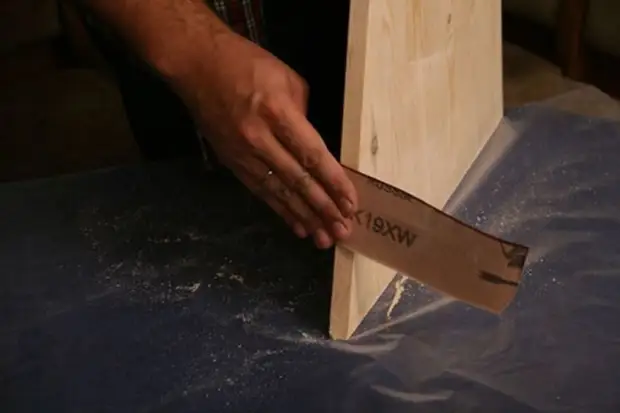

5. Smoothly polling Fauer

Grind Fan.

In order to grind the plywood slice as soon as possible, you should prepare the simplest device. A grinding material is wound on a small rail (20x20x100 mm). All unnecessary and unnecessary is removed using a mounting knife. After that, the improvised tool is screwed with a self-tapping screw to a smooth wooden surface. When it is done, the side surface of plywood rests on the design and grinds exactly the cut.

6. Relief Screwing self-built

First you need to lubricate.

It is best to drill a hole in advance. However, if there is no such possibility, you should use another way, namely, the lubricant. It is best to treat hardware silicone. In a liquid state, this is an excellent lubricant that can significantly facilitate the entrance to solid wood.

7. Gently remove the glue

The glue stops forever.

When connecting two wooden parts, excess glue is often formed. In order to remove them as carefully, it is recommended to use a conventional plastic tube. The end of the tube should be bent so that it is close to the perpendicular surfaces of the connected wooden parts. Several movements along the joint and ready.