The world of leather and fur is a fascinating world of needlework, giving many positive creative emotions. But work with natural fur is different from other types of sewing work. Knowledge of the technology of sewing fur products is required, which includes a cut of natural scooters, the rules for the selection of fur. It is necessary to master the techniques for performing the connecting seams of the skins, have work skills on the speeding machine, etc. In addition, no video tutorials and courses for working with fur can not give the most important - experience that appears only after years of work with fur.

How to sew fur at home? What is a speeding machine and can I do without it? How to cut and what knife can you cut the skins of natural fur? These and other issues are summarized in this article.

Video manual speed stitch to crosslink fur skuffs. Video in English, but understandable and so. In extreme cases, you can switch subtitles to the language you need.

How to sew fur skins manual stitch

Fur parts, in contrast to the skin, are connected either by hand, or on a special scoring machine. Sewing fur on a conventional sewing machine makes seam stretched and poor and moreover, the leather fur of the furs from such a connection method can be torn.

Manual Fur Fur Fur Schuckers Multiple, I suggest you explore one of the options for manual speed "double bunch".

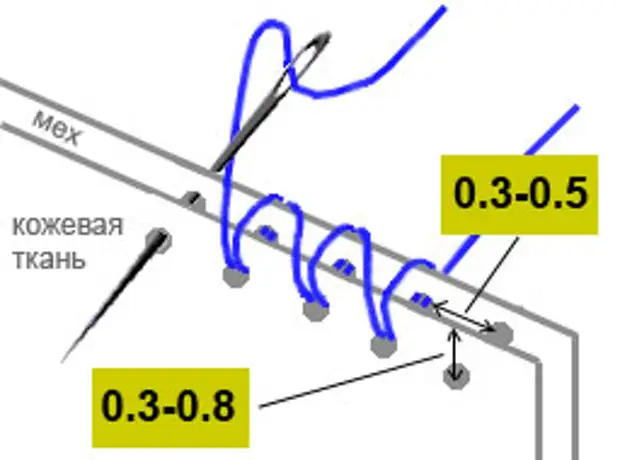

Initially, the edges of the two crosslinks are seized with hair inside so that the hair is not visible during crosslinking. The needle should punch both skins towards himself, that is, from the reverse side, but you can start from the left edge or right as you will be more convenient. The main thing is to figure out how to make such a stitch.

Love indoor or garden flowers? In the nursery "Green Gate" you can buy rooted cuttings and decenes of various home and perennial garden flowers. We are constantly updated by the anthurium and hibiscus collections. Flowers and plants are sent by mail.

Right handheld seams perform simple stitches through the edge to the right to left with a small step between stitches. Stitch forward, stitch in place, in the same holes from the needle, and again stitch forward, stitch in place, etc.

Experienced will surely make a stitch repeat, that is, the needle always passes twice in the same hole. Stitch density (0.3-0.5 cm) and stitch height (0.3-0.8 cm) depend on the thickness of the leather tissue. The thicker the fur skunk, the higher the stitch, and vice versa.

Once when they joined the skin skins with a speed seam, both parts unfold, seams lay, tapping along it with a small hammer side of the leather tissue. The seam is obtained smooth, flat and durable, and the edges of the connected parts are located.

A minor difference in the length of the two cross-linked skins can be aligned by offsetting up the edges of the skins with longer hair. In this case, the stitch must be tightly tightened. By the way, performing a manual speed-cutting seam, it should not be very tightened to the thread, it is enough to "choose" the slack of the thread. Much more important to keep the same thread tension in each stitch.

Video How to repair is proposed on the fur coat, this method is called "riding fish." Very easy way to save on the repair of fur coats. Need only needle and thread.

Some seams need to duplicate ribbon

Some pieces of fur clothing need to duplicate, such as the weld, collar, niza bending and others. The duplication of the gasket material will protect them from stretching and give the desired form.

In mandatory, it is necessary to strengthen such connectives as the seams of the armor, neck, shoulder seams. These areas are susceptible to stretching and seam tape enhances, strengthens it.

In the stores of sewing accessories, you can buy an ordinary X / B tape with a width of 1.5-2CM and use it for these purposes. There are also special adhesive tapes that will correspond to the "amplifiers". They are used in sewing products from genuine leather.

The tape is placed on the one hand.

Connecting Speed Seams need to stretch

Connected to one piece of skins need to stretch on a wooden surface. To do this, you will need small carnations and a hammer.The fur skin collected from different pieces is lightly wrapped with a wet sponge on the side of the leather tissue and then it is nourished along the edges of the cloves to the board, at the same time stretching slightly.

This is a very difficult process, you must need experience, so I will not stop in detail on it. I will only say that with the help of such a surgery of fur skins, the seams are spread, and even sometimes you can zoom in size in size.

Fur tools

Working with fur provides for the presence of a special tool. In addition to the shit, with the help of which (not scissors), the mechanic skin lifted is still used by many other tools. For example, a hammer for smoothing and softening seams, adhesive gasket tapes, special needles for manual sewing, threads, etc.

Why can't cut the skin of natural fur scissors? Because the scissors cut off the hair cover, and the seam after the connection will be strongly noticeable.

Video how to cut fur skins with a knife.

Small hammer and postal minor nails must be in a speed set. The hammer must soften the connecting seams, tapping on them, and besides, it will be needed when stretching the moistened skin on a wooden surface.

Amplifying tapes, 0.8-1.5 cm wide (glued) on the cutting edge of the skins, in those places where the fur will test the voltage, for example, in the premium, the neck of the fur coats or vest, etc.

Be sure to get a job with glue materials. They will be needed to strengthen the side of the fur coats or fur vest, collars, cuffs, etc.

Buy a good metal comb for combing hairproof. With it, it is good to "combing" the place of connection of the skins.

You still need a sewer, strong threads, special needles, glue for the skin, thimble, and, of course, a sharp shoe knife. By the way, instead you can use the usual stationery knife with a retractable blade. It is necessary, it is inexpensive and the blurred blade is easy to "sharpen." To do this, you only need to break down the bottom of the bottom of the blade (by special label).

How to choose the skin skins

Working with fur has one important advantage - you can always add the missing piece to any part or replace the furs of the fur skirts to others, since the connecting seam hides in a thick hair.

Skirts of fur of any furny animal are never perfectly the same. They differ in size, and the height of the hair, shade, and sometimes some skins have "propellars" and other defects. In general, the selection of fur is the most important skill for which the good will be valued.

The correct selection of fur will make the "monolithic" fur coat, as if stitched from one large skins, without focusing on the dock of different quality and shades of the skins. A good warden, as a sculptor, feels fur and sculpts from different pieces of the real work of arts, that's why tailoring fur products is the most expensive service atelier.

Some specific recommendations for the selection of skins are difficult to give, but when sewing, for example, a fur vest, the best pieces of skins (backs) put on the center of the shelf and back. Side parts of the skins are preferably installed in other places, for example, in the side seams.

Connecting different pieces of fur skins, pay attention to the height of the fur and its shade. Attach them with each other and compare if you are suitable, connect together.

How to sew fur skins on a frown car

Fur skins are stitched by both manual speed seam and on a frown car. To perform a speed seam on the machine, the skin in the scene is folded with the hairproof to each other, carefully fill with the index finger or the hair sewing inside and stitch the edges of the skin. Height and stitch width adjustable.

The thickness of the needle and thread must match the thickness of the leather tissue. Color the threads are not under the color of the fur, but under the color of the leather tissue, then they will be less noticeable on the front side of the skins.

When working on a frown machine, you should carefully refuel the hair between the skins, since the speeding machine will "lay out" the hair in the seam, to pull out that it will be very difficult. In addition, it can lead to a failure of the speeding machine, to pass the stitches, breaking the needle, etc.

For sand skins and foxes use threads No. 80, for thin rolling skins - No. 50, 60, for the remaining skins - No. 40, 50.

Speed seams after connecting smoothed a shoemaker's knife or light hammer with a rubber sole.

You can cut the fur only with a special shoe knife along the reverse side of the fur laid out on a plastic board or plexiglass. Cut into a knife on a wooden surface is inconvenient, the tip of the knife will constantly crash into the board. If you cut off the skin of fur with scissors, the part of the fur on both sides is delivered, and the joint will be very noticeable.

I advise novice tailor counterators at first to work with the old fur, but not yet lost their aesthetic qualities. In addition, such fur can be slightly updated if you combine it with genuine leather and put new fittings.

In this video you will see how the frown machine works. Especially for you, we sew two small pieces of fur.

The most resistant wear is considered to be fur

Fur shkurok has an indication of sponsors. The durable and resilient to the overseas is considered to be a otter fur. It was the otter that was honored to be a benchmark for all furny animals, on it and compare fur fur. Even a sable fur is inferior to her by strength and wear resistance.So, if the fur Otters is 100%, then a sable - 80%, minky - 70, sand - 65, doodle - 60, foxes - 50, ondatras - 45, proteins - 30, ermine and column - 25, rabbit - 12, crot And Suslika - 10, hare - 5.

Fur clothes care

Do not put naphtaline balls in a fur coat. Some fur, including people, are allergic to naphthalene.

Protect natural fur from wiping, such sites will very much become a fur coat.

Washed and elongated fursions on the fur coat may appear when driving a car. Try not to drive in a car in a long fur coat, it is inconvenient and quickly spoil its appearance.

Natural fur should be protected from direct exposure to a variety of chemicals, as well as spirits. Hair cover from this can lose its glitter, and skin fabric elasticity.

Try to avoid strong moisturizing fur clothing. If you still got under the sleet, dry the fur coat or fur vest at room temperature in a ventilated room, but not near the heater.

In this video, you will see how to easily sew the skin on a sewing machine of the type Podolsk, setting the Teflon paw on it.