If you have old wheeled wheels, then do not hurry to donate them on scrap metal, you can make a good street hearth. That was what the master self-leafer with Nick Makerneer was enrolled. In the manufacture of the focus, the Master put the following tasks:

-Side should be remotative. Those. It can easily replace the burned details.

-Products of operation. Those. It can easily load fuel and remove ash.

-Om should be visible and the oven should not smoke.

Tools and materials:

-Ham with cutting and credit discs;

-Welding equipment;

-Drill;

-Cretected drill;

-Metallic brush;

-Class for metal;

- welding magnets;

-Cern;

-A hammer;

-Tisci;

-Mary tape;

-Beling capacity;

-3 steel automotive disk with a diameter of 15 inches;

-The brand drum with a diameter of 14 inches;

-Remoty disk (diameter about like a drum);

-Bolts;

- grill;

-Proof-exhaust sheet;

-High-temperature paint;

-Breaker;

-Dishwashing liquid;

-Sponge;

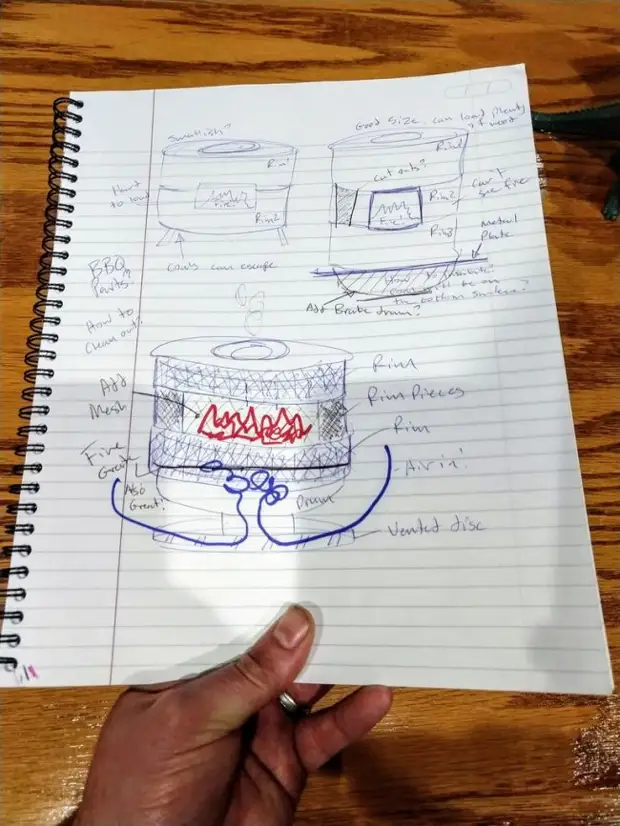

Step One: Sketch

Starting a master with a sketch of the hearth. The master has already had experience in making such products. From the experience, he concluded that the focus with the furnace door is not entirely comfortable in this kind of products. In the lower part of the focus, discs will be located out of a thicker metal. The middle part will be closed by a sparkular sheet. And the top will also be installed discs.

Step Two: Lower

The lower part is the brake drum and brake disc bolted. The brake disc has holes for ventilation and through them will be carried out from the bottom of the air supply to the center.

Step Second: Trimming

One of the disks the master fully cuts the middle part. It welds three plates cut from another wheels. The top disk will be installed on these plates and the spacing sheet will be attached. In the loy disk, the wizard also cuts a small hole and makes the cover for it.

Step Three: Cleaning, Coloring

Before assembling, the master reads the details from rust. Then staining and thermocracial.

After drying, the paint needs to simply collect the oven, load fuel and ignite.

All is ready.