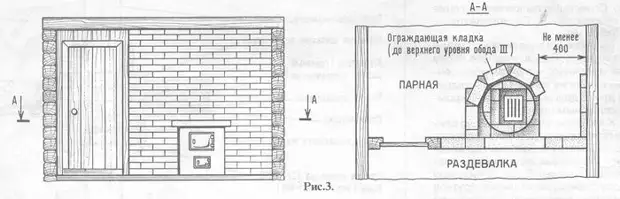

Recently, metal furnaces have recently obtained: they quickly warm themselves and warm up the room, require some firewood and with a successful design allow you to organize or sauna, or a Russian steam room. But, unfortunately, the furnaces coming on sale are often intended either only for the sauna, or for the Russian bath, but with a large tank of water. The article describes the self-made structure of the furnace of small size (Fig. 1), easy to manufacture and characterized by high efficiency. For its manufacture, the material that came into disrepair, wheel rim from the ZIL-130 car was used. They have optimal dimensions (height 250 mm and diameter 500 mm) and just a wonderful thickness - 7 mm.

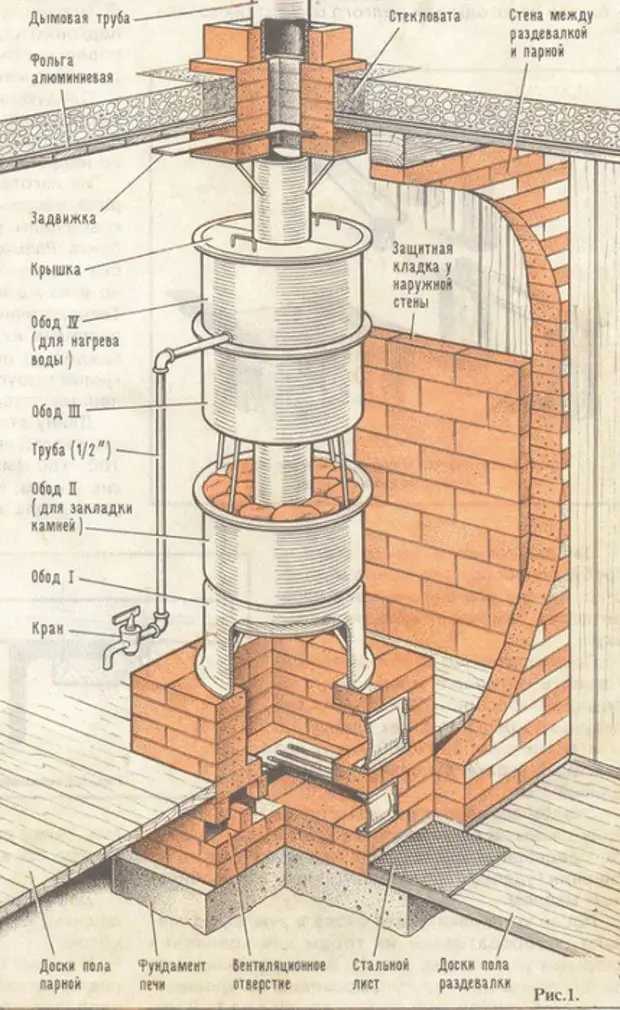

Total needed four rims: two of them - without the bottom, and the other two have a welded disk with holes. In addition, we need two steel pipes with a length of 500-600 mm and the thickness of the walls of 5-6 mm, about 60 pieces of brick, confusion and cooker doors, valve.

The lower and middle part of the furnace, where the temperature is highest, are laid out of red burned brick, which accumulates enough heat for drying the bath. In purchased iron stoves you will not get. Installing the flue and confusion doors in this design is quite simple. The furnace is placed on the clay in the Pollipich. Its dimensions are 625 x 625 mm.

A design of two rims is installed on the furnace: the bottom - without the bottom, and the top - with the bottom facing the furnace. The rims are welded with each other along the outer edge with a solid seam.

To the top rod (Fig. 2) in the center, the pipe is welded, and the holes along its perimeter and the lateral grooves are welded with steel liners with a thickness of at least 5 mm. To the lower line with steel rods, a reflector is welded - a steel disk with a thickness of 5 mm and a diameter of 120 mm is less than the internal diameter of the rim itself. It changes the direction of movement of gases, increasing the return of heat of rim I and the bottom of the rim in which stones are laid. Reflector is useful to make concave.

Rim III with divider serves for additional heat transfer. It keeps on four rods, welded around the perimeter of the bottom and resting in Rim II. All holes of the rim III, except the central, are welded with liners with a thickness of 4 mm, and in the middle, the casing with an internal diameter of 10-30 mm is greater than the outer diameter of the pipe. When assembling, this space was filled with asbestos cord (you can fill clay).

The divider (see Fig. 2) is made of 4-mm steel. The gap between the divider and the rim is 30-40 mm. Rim IV is a boiler for water heating. Such a mutual arrangement of the boiler and the heater allows you to effectively select heat from passing hot gases in the middle part of the furnace and, moreover, getting hot water. Capacity of the boiler - 40 liters. This is enough for five to six people.

The bottom of the boiler - from 4-mm steel. In the center of the bottom, the hole and flush with the bottom is welded pipe, to the top of which the steel platform is welded under the brick base of the chimney. When assembling the boiler was mounted on rim III through a lining from asbestos cord with clay. To the bottom of the boiler welded a tube with a crane below. At the top of the boiler is closed by a removable lid consisting of two duralum half a thickness of 2 mm.

The valve in the pipe is installed after laying on the clay of the first row of bricks. Pipe - square section, one and a half brick width. This design provides reliable fire safety and simplifies the installation of the valve. Above the attic smoke tube is made of a thick-walled asbestos-cement pipe dia. 160 mm. It should be noted that the weight of the smoke tube should not exceed 50 kg, as it relies on the bottom of the boiler.

The furnace can be made in any workshop where there is an electric welding. The design can be collected from individual independent parts, which are easy to deliver to the place of installation in the trunk of a passenger car. One of the options for installing such a furnace and is shown in Fig. 2.

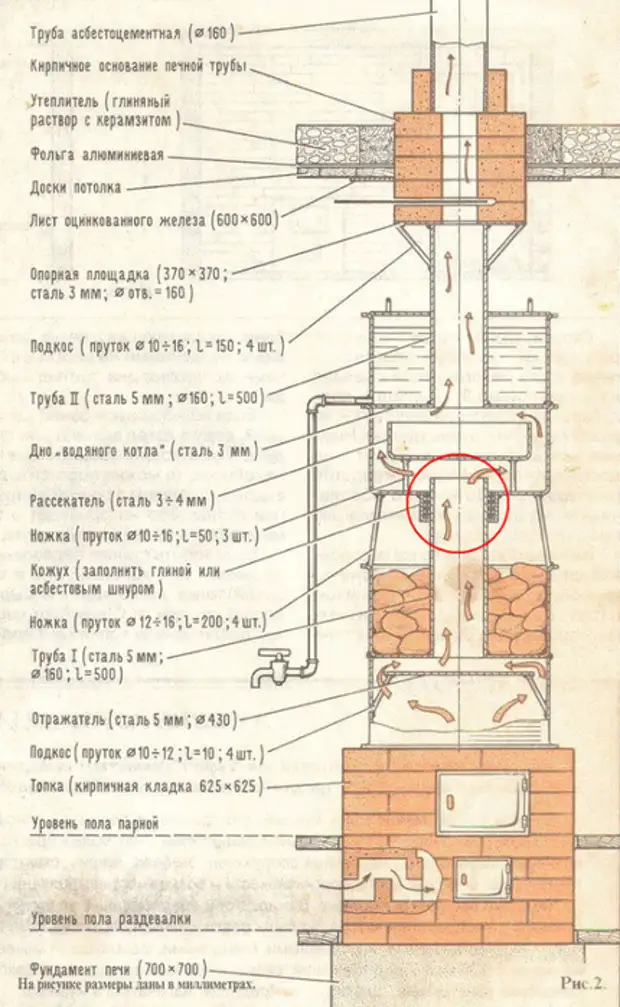

The wall separating the steam room from the locker room passes close to the stove and for safety is made of bricks (Fig. 3). The approach to the infancy and fuel doors is from the locker room, which is very convenient. The lower part of the ash bar comes under the floor board pair through a hole of 60x130 mm in size, which ensures efficient ventilation of the sample space. The lower rim during the furnace is heated by the hot. In order not to burn, the rims I and II, I laid a brick on three sides, laying out their chess order. The wooden wall of the bath, adjacent to the stove, is protected by the bricks laid on the edge to the bottom of the third rim.

If you use the bath as a sauna, the water in the boiler should not be poured, and if the hot water is still needed, then you can put two buckets of water next to the oven with the outer wall. This will not lead to a noticeable increase in humidity.

If you drown dry birch wood (with good rod and high firebox, both raw firewood are easily burning), then at 0 ° C outside an hour after the start of the furnace, the temperature in the sauna reaches 120 ° C. To maintain this mode, it is enough to make the burning 3-4. If the firewood does not pine, then after a while the temperature will fall, and you can go through a broom, leaving water on hot stones. If you just need to wash, you can pour water to the boiler, 40 l, which is heated for half an hour to 60-70 ° C.

The bath with such a furnace made by the author is operated for three years. The design was successful - already a few neighbors built themselves like this.