Let's start from simple to complex:

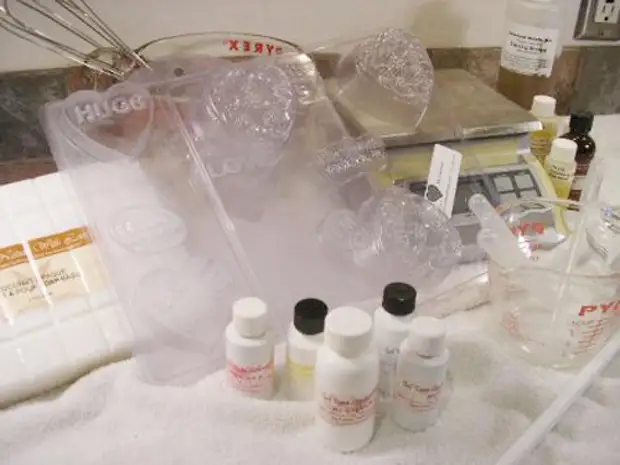

- Cooking and subsequent molding from the finished industrial soap, more often than children, as it contains the smallest amount of additives, usually use soap odor, so that the characteristic smell of children's soap does not spoil the bouquet of essential oils;

- Ward soap from an industrial soap base that has neither smell or color. The base is two species: transparent (glycerin) or matte (from coconut or palm oil). The soap base can be bought in specialized stores;

- Actually Cooking soap "from scratch", according to traditional recipes, a process that requires appropriate preparation and compliance with precautions, since in the manufacture of soap it is necessary to use aggressive alkali. Soap is cooked from naturally raw materials: vegetable or animal fats with the addition of caustic soda or potash, in the process of cooking fats are "washed" and converted into soaps.

Below are six main steps, following which will help with their own hands make real works of art from soap on home kitchen.

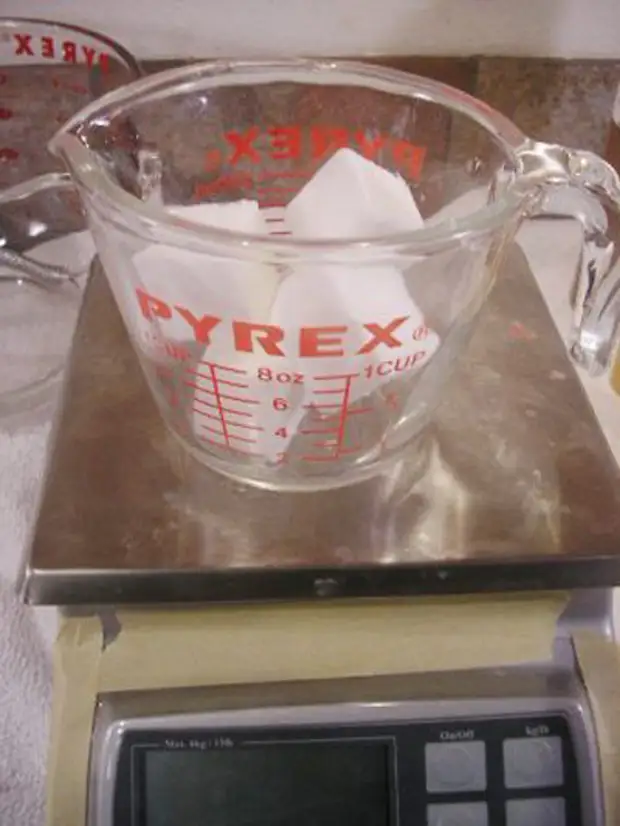

1. Plant melting: Previously need to grind the base: cut into pieces with a knife or grate.

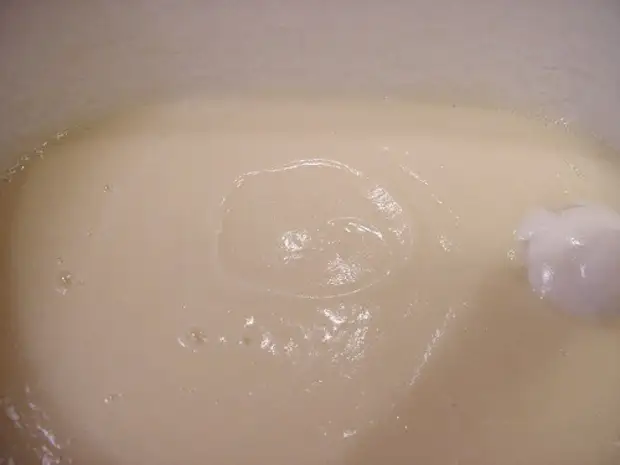

You can melted in two ways, but in both cases the basis melts without direct contact with the stove. The first option: do it in the microwave oven, the second melted on the water bath.

The secret of good soap is that heating must be carried out only until the basis is melted.

2. Adding Essences: Professionals advise to begin mixing supplements from Essences. Because to a greater or lesser extent, they can change the color of the base, the most unexpected way.

For example, some coconut essence varieties are designed specifically for soap, paint white base in pink color.So, when the base is no longer exposed to heating, it is necessary to introduce an essence, it can be favorite perfumes, aromatic essential oils that can be bought in a pharmacy, or natural foods, such as vanilla or honey. If essences purchased in a specialized store and designed specifically for soap are used, the approximate amount is 1 teaspoon (5 ml) for every 250 grams of the base; To be more accurate - 2%. If you use food flavors, then their number can be slightly increased.

3. Tining: Almost everything that your imagination can be used as a dye for the manufacture of soap. When adding food dyes, it is worth considering that they are discolored with time. There are many types of dyes that offer specialized stores. Dye should add a little, since if necessary, you can always add color.

4. Other additives: If you want soap made by your own hands to have moisturizing properties, you can add various vegetable oils, such as almond oil, wheat sprout oil with vitamin E, mango oil, etc. Do not add more than one tablespoon per 500 grams of the base. At this stage, you can also add the components that you have chosen as a scrub, it can be ground coffee, sugar, ground herbs or something else.

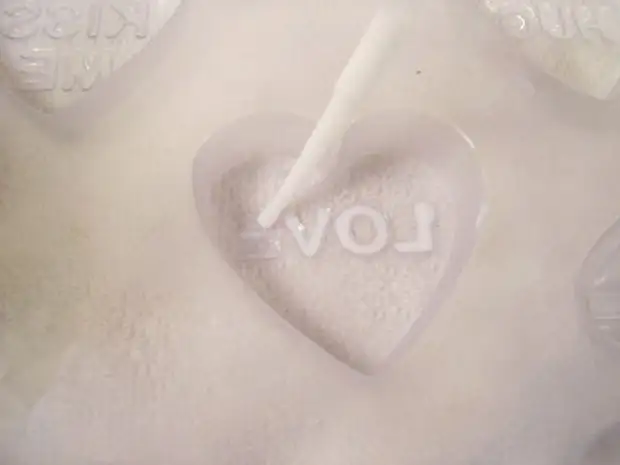

Adding too much oils contributes to the fact that soap is obtained too soft and wet, and therefore does not harden.5. Spilling in forms: Any kitchen shape, plastic boxes or trays from cheese, butter or pate can suit as forms. You can also use cells from chocolate candy boxes, molds for ice or children's sand molds. Suitable anything, just look back on the sides !! So that later it was easier to extract dried soaps from the molds, they should be lubricated by corn oil or liquid petroleum.

As soon as the soap is disengaged in the form, air bubbles can form on its surface. You should prepare an alcohol pulverizer in advance (you can use vodka). One push on the spray gun is enough to downe bubbles instantly.

6. Extract from the molds: If you forgot to smear the form, then you have to work to remove with soap with a whole piece. But if the molds were previously lubricated, then after a few days of drying, it would not be difficult, to remove soap from them.

If there are difficulties with extracting, Mirovetov recommends putting a mold for 5 minutes into the freezer (but no more!), After which itching the mold of hot water, after these not difficult procedures, soap should be easily separated.

Soap is ready to use as soon as it hardens. If you are not going to use it to take it to take the best in your life of the soul, it is worth fully wrapped the lump in a polyethylene film so that soap does not dry.

Source: Mirsovetov.ru.