Last year, the next purchase of the mangal was burned by the bottom. I quickly made an insert into it from galvanized, but in the process of manufacturing a new bottom I remembered the old gas cylinder in the barn, which lived there for twenty years. From where he took a father-in-law, it's not known to anyone, but I know for sure that he wanted to make a brazier from him.

This year my hands reached him. After a careful inspection it turned out that the balloon is not gas. Rather, it was the old hydroaccumulator of the Times of the USSR, when two families lived on our dacha, there were water pipes and coal heating in the house.

Billet for mangala

The size of the cylinder is just under the normal mangalu, and despite rust, the metal "alive." On the one hand, he was carved a rectangular hole, so it would not do a barbecue with a lid.

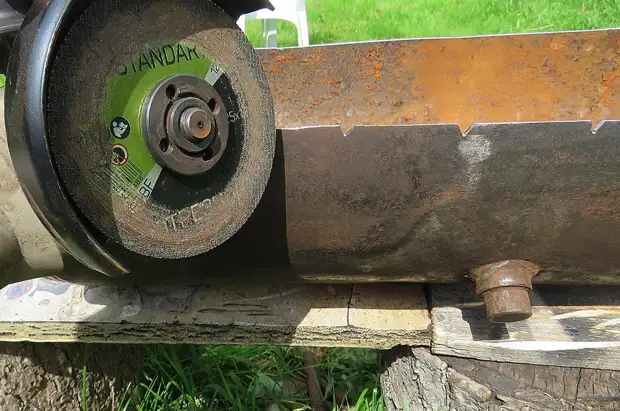

I thought for a long time, in what proportions to cut it, because there was no spare cylinder for the second attempt. I decided to cut a little higher than the center, so that the brazier would be deeper. Just on the assembly there will remain a pipe, which will then serve as a pen for carrying a manga. Made a marker marking. He took a brandy with a disc on metal and after 10 minutes. Conditionally the upper part.

Now it was to remove rust from the old half halflone. It is unrealistic to make this operation in the room - it is necessary to grind only on the street. Changed the cutting disk on the grinding nozzle. The turns on the grinder reduced, because on the maximum turnover of the skin is quickly wearing, and slices can fly from it.

Grinding the billet for the mangaal for about 30 minutes, removed most of the rust. Rusty dust stood a post - it's good that a light breeze rose and dispelled dust along the site.

Then he walked around the ballulon with a leptal nozzle, and rust almost left. Inside grinding the workpiece will not. A couple of times I will clarify the "trough" by open fire - the rust itself will fly away or unwind.

Then, at the edges of the mangala, I cut the triangular grooves at a distance of 6 cm. They will allow fixing a flat chapter on the edge.

It was interesting to me how much metal remained after grinding. Made a couple of measurements around the perimeter - wall thickness of about 2 mm.

I make collapsible legs

I had a square metal profile with a cross section of 20 × 20 mm. I will make legs out of it. They will be filmed that the Mangal has occupied less space when stored.

Cut the 25th profile on the segments of 10 cm long. Then, from the 20th profile, 4-year-old legs were cut (the height of the standard table) from the 20th profile.

In the segment, 10 cm long drilled a hole with a diameter of 8 mm, put the leg into the segment and drilled in it the same hole. When combining the holes, the segment and the leg will connect the M6 bolt.

The next day, segments from the 25th profile to the billet for the mangala.

In the corners of the "trough", the cuts of the 25th profile will be inserted legs.

Paint mangala

Yes, I was not mistaken - the brazier will really paint with a special heat-resistant enamel. In the description, I read that it can withstand temperatures up to 750 ° C. According to my assumptions, the MANGAL is unlikely to heat up stronger.

I was lucky with the weather: the sun was shining on the courtyard, + 28 ° C, as on Canar, and the rain forecast did not promise.

Before the painting leg and the brazier on the outside, I degreased well. To paint the universal heat-resistant enamel Vixen. For this summer, I just "hooked" on aerosol compositions. It turned out that it is convenient to work with them, the paints dry quickly and should not be spent on consumables such as brushes and rollers. In addition, the volume of cylinders is less than the cans with paint, which is good for small works. Painted - and you don't break my head, where and how to store the remnants.

The legs laid next to the mangal, undergoing two cuts of the boards under them to lift them over the surface of the table on hemp. At first, a jet was held on the legs - the paint was going to bed smoothly. Then she struck the first layer on the balloon.

Already after applying the first layer, the brazier began to look very decent, just like a new product. At some point it seemed to me that the coating is very similar to the industrial. Work well in the sun: it can be seen how the paint lies and dries right in front of the eyes. "On the low" at temperatures above + 20 ° C, the heat-resistant enamel Vixen dries in 15-20 minutes., After that, you can apply the 2nd layer.

While he watched the drying of the first layer, felt a vague concern. "M-yes, it seems that you forgot to make holes for ponds," my inner voice suggested.

Quickly stated the places under the holes for the imagination at an altitude of 7 cm from the bottom point of "trough" and drilled holes with a diameter of 8 mm in a step of 6 cm. They, of course, had to be made before painting.

Painted the cylinder and legs with the second layer. Now the product according to the instructions should dry 24 hours. At the sunset put a brazier to the house: there was no smell of paint.

The next day made a finished product on the lawn in front of the house: it was necessary to test it. Lit in the new mangale a small bonfire from the boards from the old fence. The boards burned to coal - the paint became even stronger, since the thermoemal completely hardened when heated. After that I osmpelled and loaded the full brazier birch firewood. They walked safely, allowing enough coal for kebabs.

So, from the old hydroaccumulator and square metal profile, I got a brand with a 70 cm length preparation zone, a width of 29 cm and a depth of 17 cm. The legs can be removed, and the MANGAL himself is to enter the shed to winter.

On the next weekend we built an excellent kebab for the whole family. The coals were hot for a long time, it means that I calculated everything correctly with holes. With paint after two full loads of firewood, nothing happened, so I officially declare: the brass resist the test drive!

Source: https: //7dach.ru/racoon/mangal-iz-starogo-nagrevatelnogo-kot ...