The master class is devoted to the production of silver wire. The process is quite simple in the presence of the necessary tool. Silver wire is a very necessary and demanded material in the process of creating jewelry.

Required tools for the manufacture of silver wire:

- gas-burner,

- rollers

- Fileric board,

- crucible,

- forceps,

- Titanium stick

- mold.

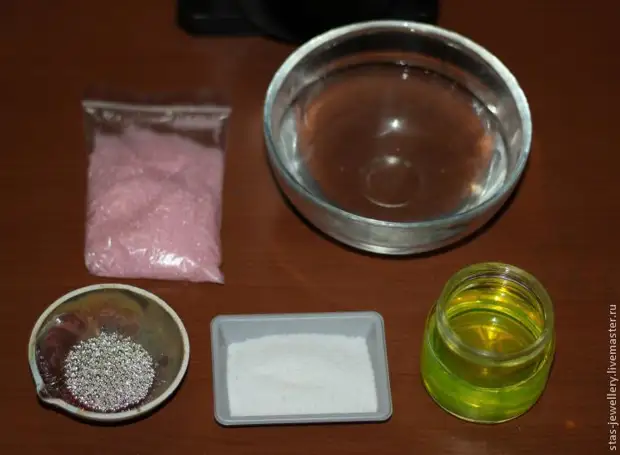

Materials and chemicals required for the manufacture of wire: Sterling Silver Alloy in the form of granules, borax, flux, beat.

For the manufacture of wire, I use a finished alloy of 925 sample silver in the form of granules.

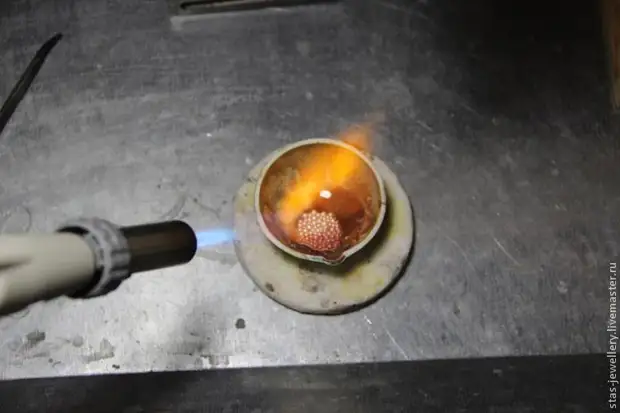

At first I am in a crucible silver in a crucible and heated it to red, then add a forcep of the borants to protect the alloy from oxidation (creates a film that protects against the ambient air).

We melm silver, stirring the titanium stick until silver is able to flow.

We pour metal into the table, which periodically heated, i.e. It does not have to be cold before you begin to pour liquid silver into it. If the squeezing is cold, the metal will harden instantly when contacting a cold table, and you will not receive the block of the desired form. There are several sizes of forms on the table, you need to select the size in which the resulting bar does not exceed the size of the roller clearance.

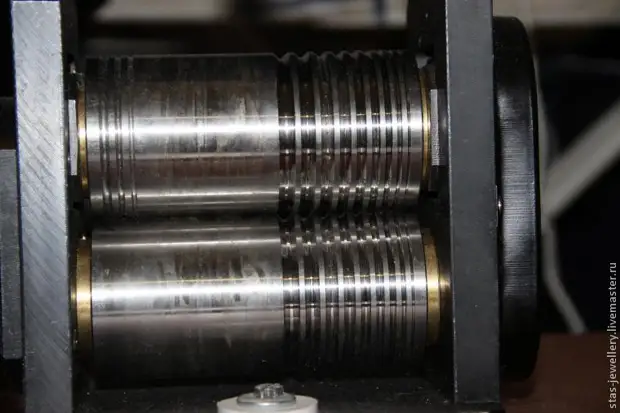

We roll the silver bar through the rollers, gradually reducing the gap. On the rollers there are a streams of various sizes of section, through which bar rolling from a larger size of the cross-section of the streams to a smaller, depending on the desired wire diameter. In this master class, I made a wire with a diameter of 0.8 mm. When moving to a smaller size of the swath, it is desirable to burn the bar of the gas hamlength bar (before annealing it is necessary to make a flux bar for avoiding oxidation), because In the process of rolling under the action of pressure, the mechanical properties of the alloy (hardness, plasticity ...) are changing, as a consequence of changes in the crystal structure of the alloy. During annealing, the crystal structure of the alloy is restored and the mechanical properties are changed to the increase in plasticity and reduce alloy hardness. After each annealing, a rolled bar is soapying in a bleach to eliminate flux residues, as well as remove all sorts of solid particles.

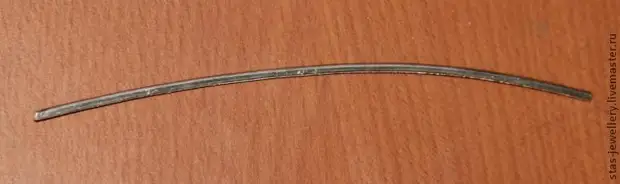

Before drawing, you must make sure that there are no pollution and flux residues on the rolling wire, to remove the flux you need to lower the wire into the beat. Correct the wire to the end of the wire.

Slightly heated wire lubricate with natural bees wax to reduce friction. On the filler board there are signed openings of various diameters. We fix the filter board in a vice, insert the pointed end of the wire into the hole of the corresponding diameter and stretch with the help of pliers.

Pull the wire to the desired diameter, moving from more to a smaller hole, and do not forget to periodically flaw the wire and lubricate with bees wax. You can use the finished wire to create jewelry.

Separately, I want to describe the process of ignoring the wire. Since the wire is thin separate coats of wires can be melted during annealing. Before the annealing, the thin wire must be sucked so that the coils fit together, as dense as possible. It is necessary to avoid melting.

It is advisable to produce wire yourself only in cases where you use it quite a lot and constantly or have the opportunity to implement it, because Wire production tools are not cheap.

Thank you for paying attention and got acquainted with my master class, I hope it will come in handy.

Sincerely, Sizar.

A source