Buy light, quick-proof trunk for foreign cars is not a problem. But for the domestic "Zhiguli" such a device will have to be mastered on his own, as Vadim made from Tolyatti.

Car trunk on the roof - the thing is good. It is installed on almost any car to carry large-sized things that are not placed in the car's cabin - for example, skiing, bicycles, snowboards. The gathering of such a trunk is simply necessary to deliver long construction materials weighing up to 50 kg. Of course, it is possible to use a trailer for this purpose - but only in the case of targeted, pre-planned trips.

Constantly carry the trunk for the roof with you is inconvenient: there is strong noise from it, and the consumption of gasoline increases. Therefore, the upper trunk is usually stored in the garage or in the country and are installed if necessary. I had a situation several times when I had to regret the removed top trunk: I drove along the way, I saw the necessary overall thing, but I could not buy due to the lack of a trunk. The idea of a rapid folding trunk, which can be constantly carrying with you, has become a pressing. The removable trunk must quickly get ready, it is easy to install on the roof of the machine and take a little space in her trunk. Therefore, I decided using the details of the standard top trunk, make a new, consisting of two collapsible arcs.

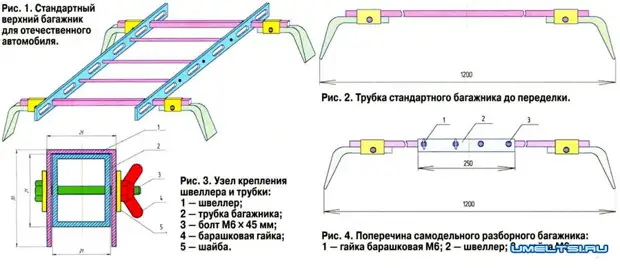

Runlying the standard top trunk (Fig. 1) , I took the attachments and two tubes of the square (Fig. 2) which saw the metal on the metal into two halves. To connect these halves, the segment of the metal pipe of the rectangular section of 25 x 40 mm applied. Cut off from him along - a second-hand channel turned out (photo 1) . The trunk tubes fit in it, as in the coupling, with a small backlash, that even well.

Drilling four holes in a chaserler and tubes (photo 2) On the one hand, the channel was consolidated with a tube with bolts with ordinary nuts, and on the other - it turned out a collapsible knot with bolts and bars (photo 3) . For the assembly of the trunk, you just need to insert a tube into a channel, aligning the bolts, insert bolts into the holes and secure the design with carrying nuts.

My trunk is installed for two minutes easily and simply, since the factory fastener has not changed. The design gives the stiffness to be transported cargo, which binds into a single whole trunk (photo 4) . My collapsible trunk takes little space (photo 5) And freely placed in the car trunk.

I have repeatedly envied buyers of plastic panels, trying to shove them into the salon of the car, looking at how I quickly installed the trunk and loaded lungs, but long purchases (photo 6).

one. Steel profile channel 25x40 mm.

2. Holes in a channel I drove on the machine, holding a blank in the vice.

3. A node of the combination of halves of the smooth of the homemade trunk.

four. Fastening the cargo to both crossbars of the collapsible trunk: it increases the rigidity of the structure.

five. The disassembled top trunk (both are cross with regular fixtures) does not take up much space.

6. An example of fastening a plastic profile on the top trunk of the car.

The author is Vadim Mars, Tolyatti.

A source