You just have to see it! Many decorative fireplaces do, but I have never met such a tie beauty. See the MK on creating a miracle from the master Phoenix

The false fireplace can decorate your home, make it cozy, adds uniqueness and individuality to your interior. Especially if he is made with his own hands.

I will start with the fact that I did a similar thing for the first time, and therefore I needed a lot of time, I was constantly stopped, I reworked something and improved ... The idea was that the tile from the gypsum reminded the vintage tiles. How I got to judge you.

So, let's begin. I used the finished form, as well as an independently made (cast from silicone) for small parts, plastic form from packing of biscuits of two sizes, form for baking flowers from plastics (ready).

The entire set of materials looked something like this:

The remaining auxiliary tools can be seen in the process of operation: a gun for mounting glue and silicone, a hacksaw for metal (for trimming gypsum tiles), pencils, tanks for mixing plaster, etc.

How to make gypsum blanks, I think you know for convenience I took 8 forms for casting a large tile and 8 for a smaller tile, each noted the level of the fill so that they were about one thickness.

The tile dries several days depending on the humidity and temperature of the air. The finished tile should be light and bright. Immediately think about where to dry and fold. Simplestly cast and small details.

I recommend calculating the approximate number of tiles and floweries and make spare. When casting and drying is finished, proceed to grinding and painting. Grinding is made by sandy paper.

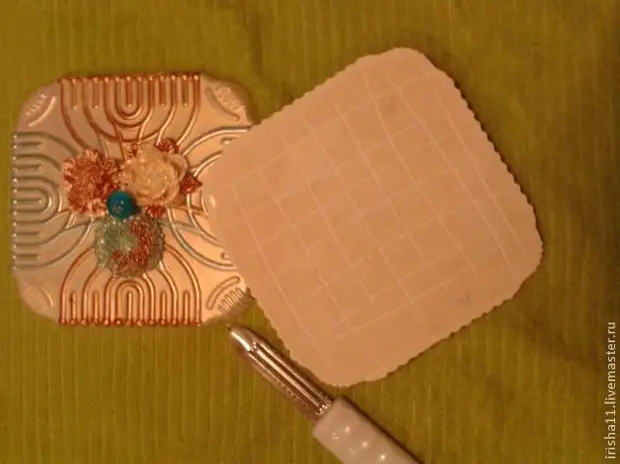

In addition, on the tile on the back side of something acute, the grid of grooves, which will subsequently make it a more reliable mount to the plasterboard. Painted marble and individual elements painted acrylic paints.

Now the most interesting thing is every tile and decor to her collect together and here your fantasy is limitless, everything is attached to the mounting glue with a gun and hands.

And so, your tile is ready and small details that you will fill out empties between tiles, too. It remains to be lacquered in two layers and dry. The fireplaces of the fireplace, I tipped in advance the finished tile and border. I think it is not difficult and can be done while the bulk of the details dries. In addition, I got a ready-made plastic baguette

The assembly took a lot of time, because all the details should be glued alternately so that they do not fall off under their own weight. It is better to do it in the rows from top to bottom, and then fill in intercutor spaces. This is a rather long and time-consuming process, but it is not necessary to rush. Tile may differ in thickness. Therefore, before installing, I sorted it in thickness, and when the glue, it was trying to glue the same thick on the same plane.

It is best to cut a tile in size this tool:

Baguette is cutting with the same hacksaw for metal and fasteners with mounting glue to the fireplace. It remains to fill all the small details of "bringing beauty".

A source