In skillful hands, the tree becomes truly magic material. In addition to the author's furniture, for the manufacture of which the valuable woods are used, the waste of woodworking is under way, on the basis of which hybrid wood is created. The tree is well gone to gluing. From the wood, a bent rafter system is made in the form of a fitted arches.

It is the flexibility of wood and the opportunity to give her any form attracted an American designer of the Foecler field, which decided to make an unusual and stylish lamp from the "wood".

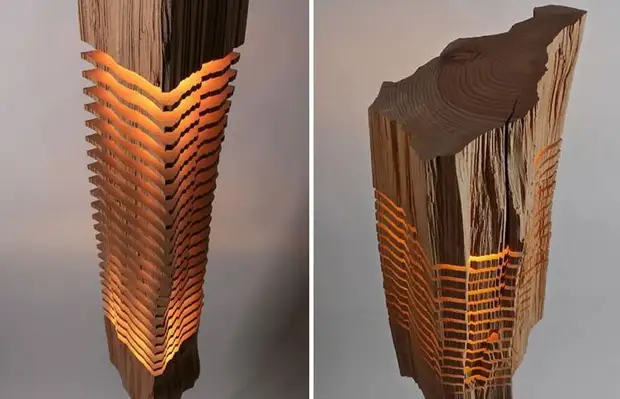

Paul decided to cut off everything too much and, thereby, to emphasize the texture of the wood. Cleaning Churbachki from the bark, the designer split them into several parts. At the same time, he did not try to achieve perfect symmetry or using machines. Colop, how the hand went. As a result, it turned out several blanks, no longer at each other.

After that, Paul cut the polenka across several parts. Next, after hanging out the core, the designer took a metal rod and drove cuts on it, and also installed the LED lamp inside.

Externally, the lamp is something like a spine, made of wood. Asymmetry of the product only emphasizes its unusual shape.

To improve the heat sink from the operating lamp into the lower part of the lamp, the aluminum radiator core was embedded.

Depending on the size of the lamp and the selected shape, it can be put on the table (for this, the rubberized legs are pasted below) or attach metal legs and install on the floor.

In order to emphasize the structure of the tree and the texture of the annual rings, but at the same time "not score" the natural look of wood, the blanks are covered with colorless varnish.

The lamp turned out so successful and in demand that Paul decided to put things on the flow and created the author's series of lamps. Moreover, none of the product repeats the previous one. Form, dimensions, width of the cut, the saturation of the light stream, which gives the lamp - all this gives the work uniqueness and individuality.

Depending on the complexity of the product, the manufacture of one lamp can take up to 100 hours.

According to the field, anyone who gathered to do a similar thing is important to find "his" tree. The designer uses Californian cypress and wood ash.

For example, the designer combines grinding with underlined gross chopped shapes.

It reveals and emphasizes the natural texture of wood and enhances the effect of the lamp.

Also, Paul advises to experiment with the distance between cuts.

By increasing or decreasing this distance or combining both methods, it is possible to achieve such an effect that at some angles of view the tree will look like a solid array, from the inside of which the muted light is poured.