A bench is put on many country sites for a convenient time. Sitting on it can be chatting with someone or just not falling in the sun. Instead of the bench, quite often place the table and chairs, so that the whole family can spend the scenes in the fresh air. These are just a few options for how garden furniture can be used.

Recently, there has been a popular multifunctional furniture type transformer that can be used for various needs. For example, a garden bench after frequency manipulations turns into a table with seats. Simply, it is beneficial and possible, besides, do it yourself.

Nuances that should be taken into account

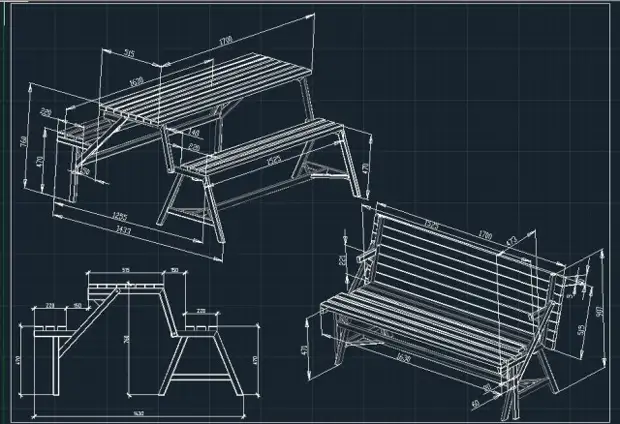

For the lowest assembly, it is better to use wood details with your own hands. To make an assembly need to create quite detailed drawings that will help navigate in the process. They can be performed both on paper from hand and in construction programs, if there are skills to handle such a software.

In addition to wooden billets, you should stock yourself with screws and prepare tools: screwdriver, saw, sandpaper, brush for processing. There is a fairly simple moving design with two functional positions: a bench and table. For one to another position, it moves with a special connection.

You can find several different options for assembling the design with your own hands, but we will look at two. Metal parts can be used in the first, and the second is completely made of wood. So, where is it worth starting?

Materials for work

The most common wood species that are used in similar designs - pine and larch. They are perfect for the manufacture of a frame. You can also use oak, but it is very hard to process.You need to choose boards without rot and defects. You will need blanks, up to 2 m long and up to 50 cm wide. For attachment, a plurality of small screws, nuts and bolts will need.

The first stage of the assembly

You need to make parts, align them, give them the shape and poll. The transformer bench can be made according to individual sizes, but quite often use a value of 1700 mm as the basis of the frame length.

The transformer design will consist of three connected parts - a table, a wide and narrow shop. The first shop will be wider, and the second is already. This is necessary in order for the frame to develop:

- For the manufacture of a wide part, you will need three parts 1700x120x20 or one-piece shield of 1700x400 mm. Two strips 34x11x11 mm will be used for the legs

- The prepared billets are thoroughly polished

- The legs are fixed on the bar, forming the letter T

- The shop should turn out to be 450 mm high

- On the bar on which the legs are fixed are screwed using chalkboard screws or shields

- There is a strut between the legs, which will provide rigidity. It connects with a similar element on the opposite side with a wooden thrill, about 1690 mm long.

The first part is almost ready. It has not yet come to the assembly of the rest of the elements, you need to check how the bench will endure the weight of one or two people. If it has withstood the load, you can continue working on the second and third element of the design.

Second Stage - Countertop and Second Shop

The second part of the design in the width will be a little already first. Three elements will be used as the legs - two, sizes 320x10x10 and one 220x10x10 mm. All billets are collected in the form of the letter A:

- Two strips of 320 long strips are fixed to the upper bar at 220 mm at an angle and between them are spacers. The distance between the first strip and the second in the lower part should not be less than 300 mm

- The spreadshells of the legs are connected to each other. On the resulting letter "A" three bars are fixed, the size of 1691x110x20 or one-piece shield

- The total width of the manufactured part should be less than the first part. To check the assembly, it is worth combining shops. If they are well connected, then everything is done correctly

- The table is made of five milking, dimensions of 1700x270x20 mm or a solid shield

- Billets are screwed to the bar 1100x40x8 in increments of 80 mm

The top of the bench is ready, now remains the movable mechanism and consolidate it between the elements. For a transforming bench could be changed, you will need several additional items.

Third Stage - Mechanism

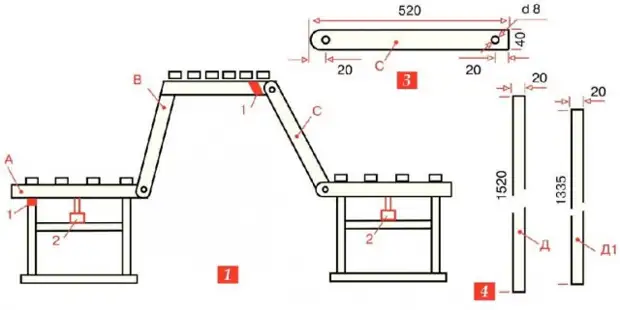

As a result of the work, we have three parts - a wide and narrow shop, as well as the table. They need to be combined with a moving element. When all the details are collected, we get a bench transformer.

- Metal and wooden planks can be used as a connecting part.

- It is necessary to connect the top bar and the shaped leg with the worktop, and then the interlaced

- Instead of self-tapping screws, it is better to use a movable bolted bolt with a nut

- The angle of the first bench must be connected to the corner of the tabletop short bar

- The second bench is connected by a long detail with a tabletop bar.

- At the end of the assembly you need to check how the connection works

Additional option

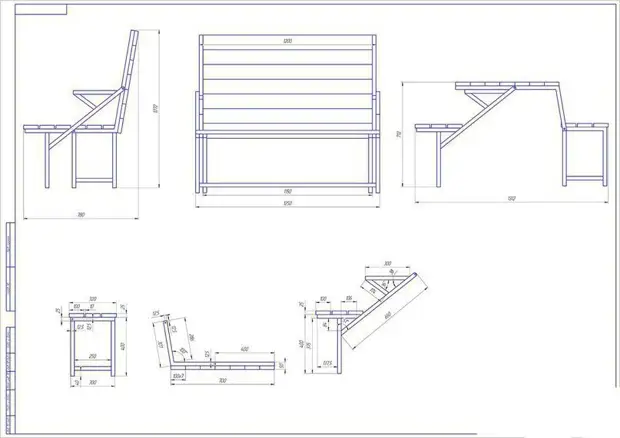

There is another type of construction that can be collected with your own hands. The transformer bench will have no six legs, but eight. Instead of two a-shaped parts, you will need four.

They differ among themselves only with the size of the upper part, which in two blanks will be less than 100 mm. Lovel designs will be absolutely identical. They are attached using a moving connection. By the end of the workpiece, which has a long top bar, screw the wooden part. It should be installed at an angle of 100 ° under the table top, connecting that with a bench. Its length is approximately half the table top length. The connection is strengthened by the strut.

The second shop is connected by an extended bar without spacers. This type of construction can be made with your own hands completely from the tree.

Finishing stage

The last stage of the assembly with their own hands was completed and it remains only to apply a protective coating. If the transformer bench will be under the canopy, there is enough moroli for still protection. In the case when the design of wood is placed in the open space under the sky, a special waterproof paint should be used. The first thing is painting the table, then the seat and legs.

After painting it will be necessary to update the layer once every 1.5 years, otherwise the tree quickly rotates. The design is able to stay in operation of about 10 years.

Conclusion on the topic

Garden bench Transformer made with your own hands can become not only a functional object of life, but also part of the garden interior. Details made of wood can not only operate with varnish or paint, but also decorate carvings and other decorative details. Only one should do it carefully, so as not to damage the stiffness of the structure.

As a result, a bench made by your own hands can be used as a table when necessary.

A source