Electrician - the science of good contact. But the truth, more than half cases of electrical wiring cases are connected with poor contact at a connection site or connecting wires. Bentally somewhere not collapsed, not compressed or undecid. In many houses, old aluminum wiring, which has served more than fifty years, has never let the hosts for his entire service life. This is the result of a qualitative work done. Today, due to the abundance of powerful household appliances, the load on the wiring sharply increased. And any miscalculation or negligence in performing electrical work can turn into a headache for the owners.

In this article, consider possible wire connections that are found in household wiring.

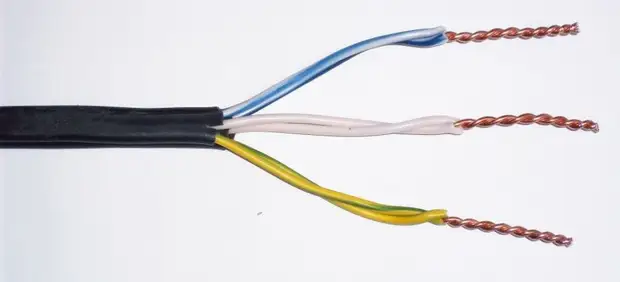

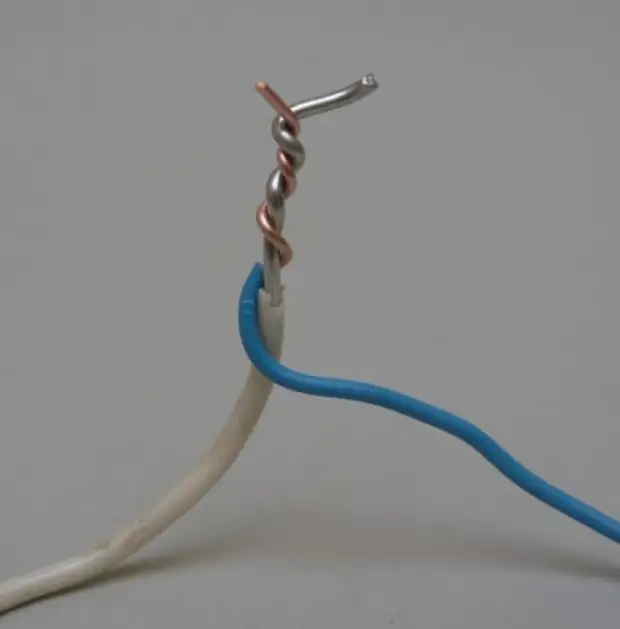

Twist wiring.

Twist is the main type of wire connection. Another thing is that a twist is not a complete connection. In order for the twist to provide reliable contact, it must be either sought, or edged or rolled. Although, if you need to do the time (temporary wiring or lighting), it will be more than enough to connect the wires by means of a simple twist. In Focus, when the permanent wiring is nestless and without scroll processing, they say - Made on snot.

How much can the wire connection can be stopped by means of a simple twist, it's difficult to say. It all depends on the operating conditions (temperature, humidity) and from loads, i.e. Currents that pass through the twist. These may be months, years, dozens of years. The reason for the unreliability of this type of connection is the oxidation of the wires and, as a result, bad contact. The consequence - a twist begins to warm up, the insulation is melted on it, which becomes the cause of short circuit. In addition, poor contact may cause electrical equipment breakdown (the effect of spawned twist).

A twist is performed using pliers. The ends of the wires are cleaned on the same length, align. The pliers captured the entire bundle and twisted.

There is a limit on the number of wires in the twist. So that the twist was reliable and did not crumble, its diameter should not be more than 1 centimeter (with a length of up to 5 centimeters). True, this is my subjective opinion. When installing, I try so that in one twist there is no more than 7 wires with a cross section of 2,5kv.mm, or up to 12 wires with a cross section of 1,5kV.mm.

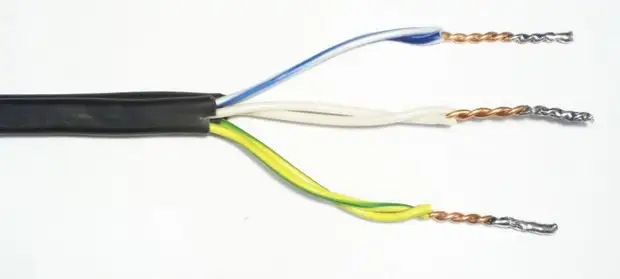

Soldering wires.

Soldering in the electrical unit is a connection of wires with a solder. In practice, having due to electrical work, it is necessary to make a twist and stranded wires.

Opeka scruitt provides reliable electrical contact of the wires. In addition, the obeying surface is protected from corrosion. In my opinion, this type of connection is most versatile.

Strangled wires are required when they are connected under the screw clip. For example, when you connect the fork or socket of the extension, the ends of the wires are recommended. Although in this case you can do and special tips of the desired diameter. Since we are talking about stranded wires, I consider not superfluous to remind, to install stationary electrical wiring you need to use wires with solid cores, stranded wires in this case are not recommended.

For soldering, we need a soldering iron with a power of 100 watts and solder with rosin. Turn on the soldering iron, let him warm up for a few minutes, we put to the place of the soldering and bring under the sting of the solder.

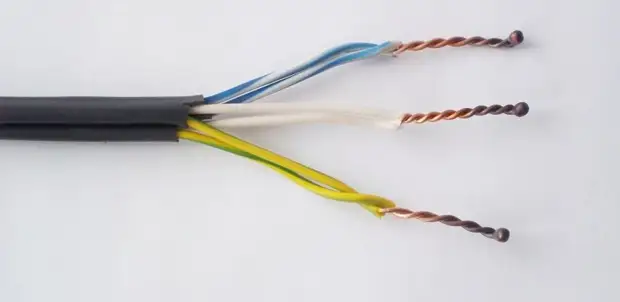

Wiring welding.

A no less popular method of processing twists is welding. In mass construction, all twists in junction boxes are welded. The reason for the popularity of this method is speed and low cost. Wiring welding takes significantly less time than soldering. For welding, a transformer with a power of 500 watts, a voltage of 36 volt or a welding machine with a coal electrode is required. It is recommended, of course, to use the welding machine - it can be optimal for welding current. For welding, we apply the "mass" wire to the twist and touch the coal electrode of its edge. The twist must be unfolded to the end to the molten metal drops on it.

Today, welding of wires is one of the requirements of the GPN (state post. Supervision)

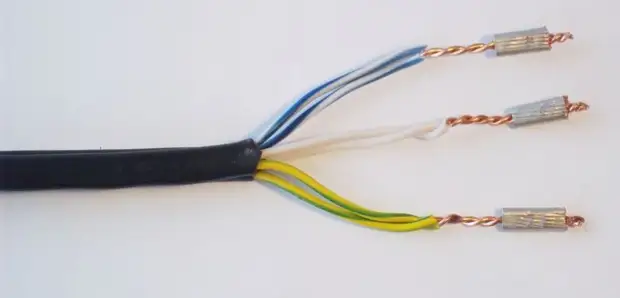

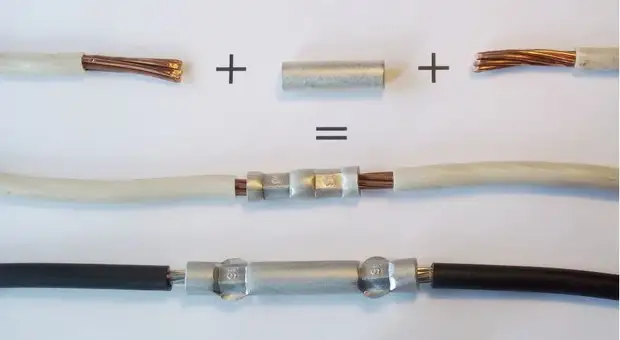

Coupling compression.

Pressing - these are connections live wires by comprising a connective sleeve. The sleeve is crimped using a special tool - press ticks. Crimping sleeves are different diameters and are made from different materials - copper, aluminum, tinted copper.

This method is one of the most reliable

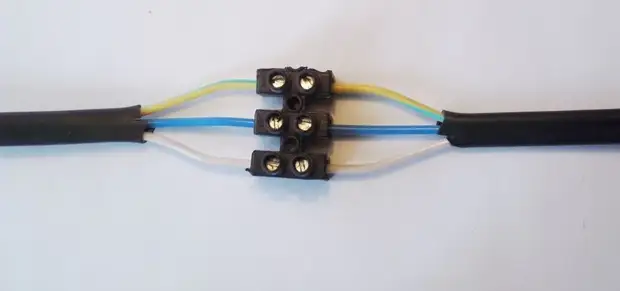

Connection of wires through the terminal block.

In the electrical unit, terminal blocks are used primarily for connecting lamps and various electrical appliances. Terminal blocks are indispensable for repair work.

A significant disadvantage of this type of compounds is that most of the very low quality terminal blocks, and, therefore, are unreliable. A poor-quality terminal block can burst when tightening (thread), which causes bad contact. The consequences may be the most different.

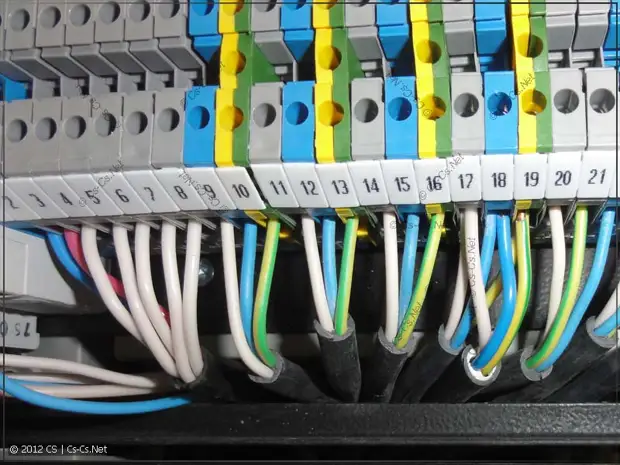

Dear and reliable terminal blocks are used in distribution cabinets, boxes.

Bolt connections.

Bolt connections in practice are rarely found. However, this kind of connection is reliable, can withstand large currents. And just in case it is worth remembering about this method of connecting wires. In this way, you can connect the copper and aluminum wires, paving the washer between the wires.

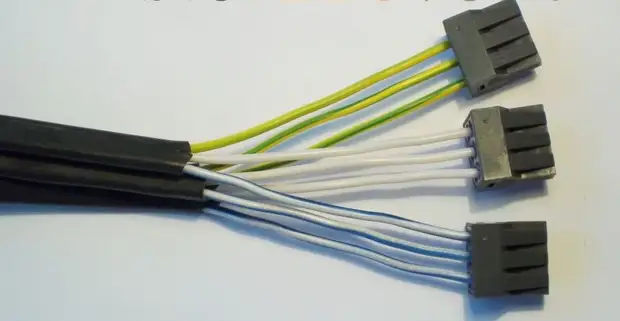

Self-slip connections.

Pretty popular method of connecting wires with self-consuming terminal blocks. The main advantage - does not require special skills, everything is simple to primitiveness. Clean the wire and put it in a self-shielding block. Contact is quite reliable.

The disadvantage of this type of connection, as in the case of screw pads, is a maximum current limit. If you plan to use self-apparatus pads in chains with powerful electrical equipment, I recommend learn their technical characteristics, whether they are suitable for your purposes. Another disadvantage is that not any self-activated pads are suitable for connecting stranded wires.

The most popular self-consuming pads of the company WAGO. The maximum current for most of the pads of this company is more than 32A, it is quite enough for household loads.

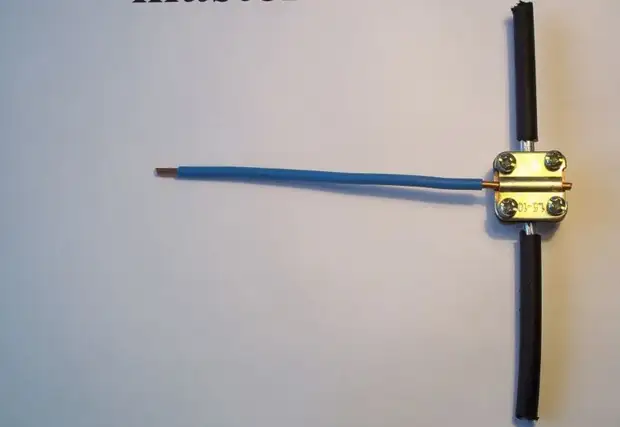

Connecting wires using cable numbers.

The connecting shift is designed for connections (branches) of lines of cables and wires. Moreover, the branch does not require cutting the main conductor. This type of wire connection is used everywhere, it can be seen in almost any driveway. As a rule, cable compounds are used to connect (branches) of wires with a cross section from 10kV mm.

In prosecution, the cable stir nicknamed the nut. So you can hear about the connection through the nut.

Perennial Application Practice Proved 100% Reliability of this type of connection. The direct purpose cable plot can be used as crimping for twists.

Why it is impossible to connect aluminum and copper wire twist.

The reasons are already two, but they are as a result of one consequence - over time, contact becomes bad. This in turn leads to its heating and all from here to the consequences.

The first reason is the oxidation of the aluminum wire. At the oxide layer, the resistance is greater than that of the aluminum itself and it leads to excessive heating of the latter.

The second reason is to loosen the contact. As you know, when heated, any body, including the wire expands. But aluminum is softer material than copper. And its conductivity is less, which means he is heated stronger. As a result of a multitude of cycles of expansion and narrowing, contact weakens and starts to warm the stronger.

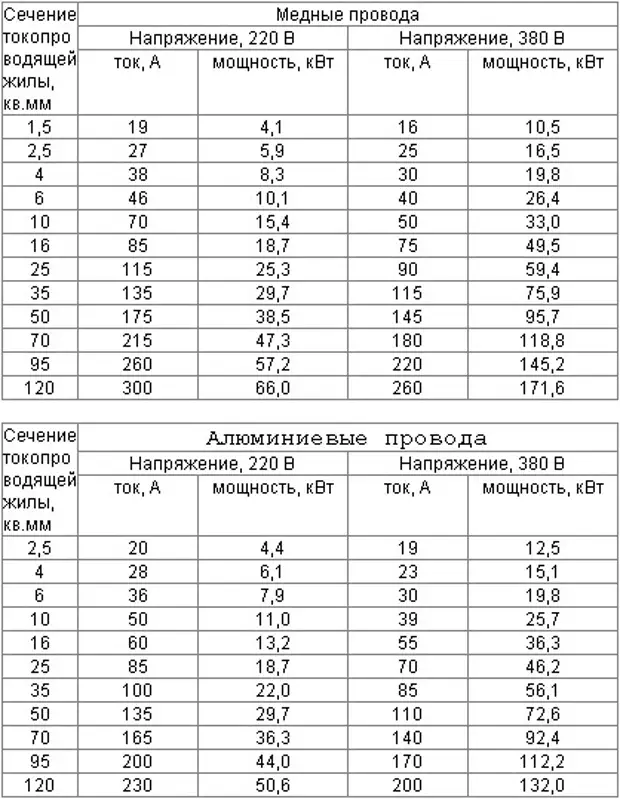

Formula for calculating the cross section of the conductor:

S = (3.14 x D2) / 4

Where:

S is the area of the circle (cross section), and D is the diameter of the conductor.

For a multi-breeding conductor (incorrectly stranded), the cross section is equal to the cross section of one wire multiplied by their number.

A source