Not so long ago I posted a couple of photos of alcohol received by me at home. Judging by the comments, this topic is interesting to people. In this post, I will try to describe the process of cooking alcohol in detail.

First you need to make Braga from which we will drive out alcohol. I used the classic brotherhood recipe from sugar and yeast.

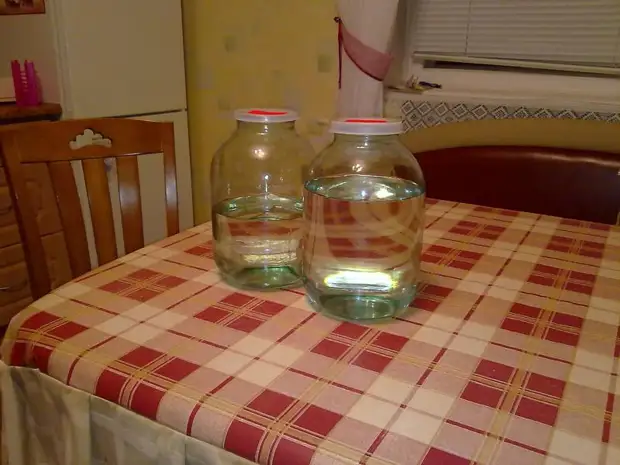

The dishes served three glass twental bottle with cork fittings for a hydraulic camp.

Yeast: Each bottle of 100 grams

Sugar - 4 kilogram Each portion

Spring water - 13 liters

Water heat up to room temperature, stir sugar sand in it and after that we fill in the bottle

Yeast is bred in warm water and fill in the last

After all the components are filled into the bottle, you need to cut off air access. For a lot of loyalty, the corkscrew tape

Bottles are put in a warm place for 10-14 days

After two weeks of waiting, when Braga stopped the "bouffer" in the hydraulic circuits and brightened, you can start distillation

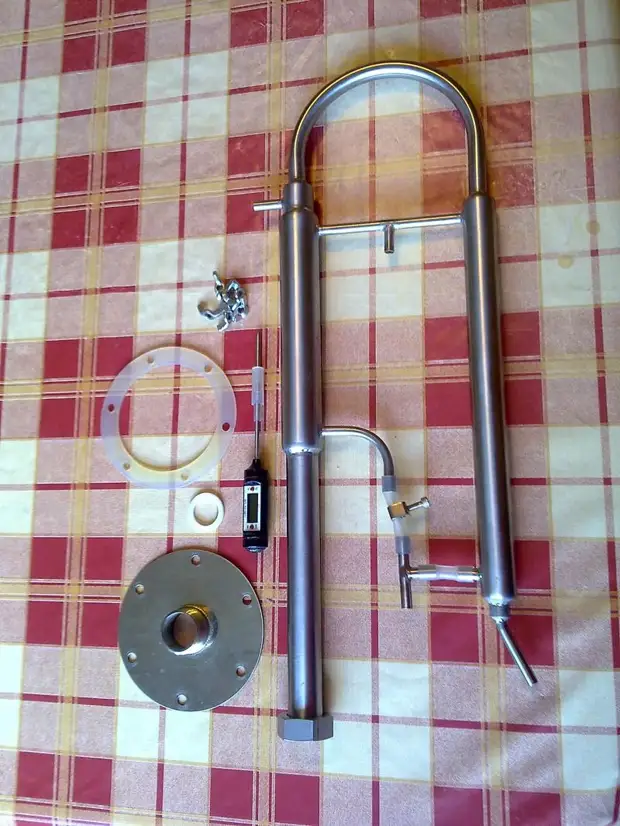

Collect the device

Cube I have 20 liters, it turns out one bottle - one portion of distillation

Pour ready-made braga in the cube

This is how the device looks like on the stove

This is a general view with hoses.

With primary distillation, the refrigerator is not used on the column, the water is not supplied to it, for this, the clamp of the corrugation is completely twisted.

The impurities during the distillation of the Braga are constantly "generated" right in Cuba when heated. The fact is that the yeast, which are inherently microorganisms, before working alive, allocate unnecessary impurities into boiling braga, including sevoyous oils. Therefore, the first distillation must be conducted with maximum heating and performance so that the yeast is killed quickly and allocated as few unwanted substances as possible. For the same reason, the second distillation with separation on the fraction is strongly recommended.

Sweet alcohol at the maximum distillation speed turns out a small fortress

As a result, I got out of our whole braga three 3-liter banks 60% and two banks 35% raw alcohol, each distillation took about three hours

Now you can proceed to the second distillation - fractional. Instead of braga in the cube, alcohol-raw poured, pre-divided to the fortress 20-40%

A small trick, hoping by me from the Internet: If you add 3 teaspoons of food soda to alcohol-raw, then the alcohol opens much "softer"

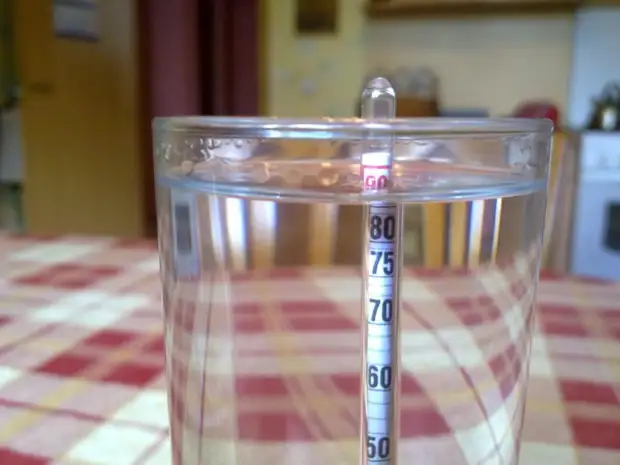

After the heating of the column to 75 degrees, water from the crane is supplied to the aerial refrigerator

For this, the clamp of the corrugation is rearranged

20 minutes of couples are completely condensed on the upstream refrigerator - the mode of operation

After that, the clip is rearranged back to the water supply tube to the ascendant refrigerator and begin slowly, with pauses after each semolution, close until the output of the head fraction appears at the output. From this point on, the selection of the first faction "goals" begins

After the selection of 150 ml for a 20-liter cube, you can proceed to the selection of the "food" fraction.

The temperature stabilizes in the area of 78-82 degrees

That's the result!

Close-up

The smaller the temperature of the cube, the smaller the performance of the system, the higher the product strength. In the process of distillation, the temperature in Cuba grows. "Food" fraction is selected to a temperature of 87 degrees in Cuba. After it is not possible to keep the temperature below 87 degrees, you need to change the receiving container and collect the "tail" fraction.

The second distillation occurs much slower than the first, she took about 12 hours, while I spent only half of the resulting raw alcohol.

That's what happened

It is believed that at home to make alcohol is much cheaper. Now you can approximately calculate the costs, considering not only sugar and yeast, but also gas, water for cooling, gasoline in order to bring spring water, and other components. But the most important thing is the time that goes to get a decent product. After all, it is received only alcohol, and in order to cook delicious drinks from it, there will be a lot of time. But for myself I came to the decision that the drink of its own production is much tastier and safer.

This is my first post, do not judge strictly, although the criticism is essentially even useful. If the topic is interesting, it will be possible to continue to prepare directly the drinks themselves.

A source