You will learn how to independently make the table with a glass tabletop from the glass package and put it in the courtyard at home or cottages.

Today, tables with glass countertops are quite popular, it looks original, fashionable and fresh, but as always the price of products manufacturer bends "above the roof." So for this reason, the author decided to make a fiscal version of the glass table, and just after repairing it remained a glass window with a size of 1x0.9 m almost even square, which for the table top is the most. The base was welded from the corner, made a frame under the installation of glass, the legs made from a metal pipe of 30 mm long 70 cm, and also for the stability of the design, the struts were welded from the reinforcement of 17 cm. Before installing the glass, the metal was cleaned and the rubber tape was cleaned and laid Gaskets.

And so, let's look at what exactly required the author to create a glass table?

Materials

1. Glass windows 1x0.9 m

2. Metal corner

3. Round pipe 30 mm 4 pcs 70 cm

4. Armature

5. Paint

6. Rubber belt

Instruments

1. Welding machine

2. Bulgarian (USM)

3. Hammer

4. Corner

5. Roulette

6. Marker

7. Mini-grinding machine

8. Individual protection products (glasses, respirator, gloves)

Step-by-step instructions for the manufacture of a glass table with their own hands.

As mentioned above the author, after repair in a private house, a glass was left, he did not throw it, and made a great table with a glass countertop. The first thing glass should be removed from the frame, wash and wipe with a dry cloth.

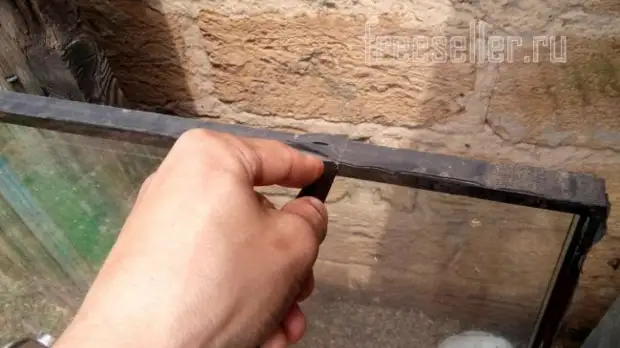

Then it is necessary to remove the rubber seal, this is done with the help of a conventional knife, fit under the rubber and begin to keep the knife from itself, thereby cutting off the gasket.

Next you need to weld the base of the table, it is made of a metal corner, and the thickness of the glass package and the height of the corner must be approximately the same, so that the table top it turns out to be smooth, for example, the thickness of the glass is 20 mm, then the corner take 20 mm.

Welded seams must be on the outdoor side of the structure.

After that, the author proceeds to the manufacture of the legs of the table, for which a round tube with a diameter of 30 mm was taken and a 4-year-old legs were made of 70 cm.

To break the legs exactly, at first the base must be put on a flat surface, and then put the leg to the place and attach the corner to set the angle 900 (it is desirable to use a special magnetic area for welding)

That's actually as a result of the work done. The cat takes and evaluates the writings of the author, according to the appearance of the Katofey is very pleased))

Next, the master decided to strengthen the design and screw the struts in the form of small pieces of reinforcement long at 17 cm.

The struts are welded in the corners from the leg to the base of the table top.

After that, the entire design should be cleared of rust, scale and old paint, the master takes the grinder (ESM) with a grinding circle and starts work.

The cleaned surface is then needed to paint, the color is chosen at will.

A rubber tape is placed on the base as a gasket between a metal corner and a glass.

The glass must be rounded around the edges because there is an acute edge, it is possible to do this with a mini-grinding machine. First of all, you should wear safety glasses, a respirator, gloves, because when working there will be many glass dust, so the safety technique is above all.

That's actually such a wonderful glass table turned out)

This table has a number of advantages: 1. It is not afraid of atmospheric precipitation and it can be safely left in an open air 2. The perfectly smooth surface 3. Fashionable, stylish, unique, unusual.

Disadvantages: glass is still fragile and with strong impact it can crack, burst, break.

But with careful use and careful caring, the table will serve not one dozen years. As you can see there is nothing complicated and completely under the power of a master person, the step-by-step instructions are represented, so we take and do. Dare friends! To secure the material passed, we recommend watching a video from the author.

A source