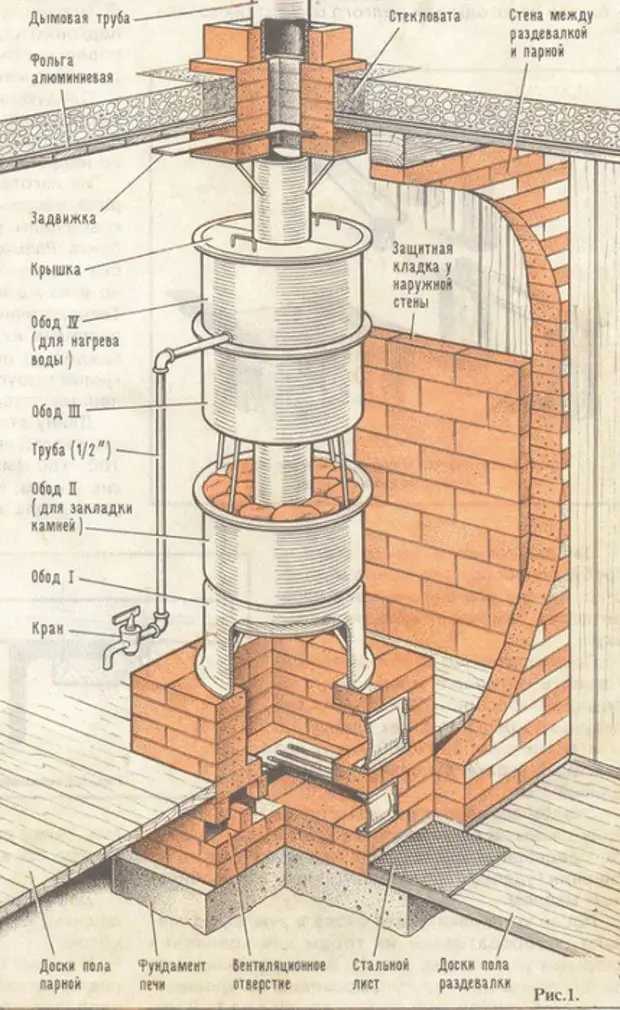

Muva nje, izimfanelo zensimbi zisanda kuthola: zisheshe zizitholele futhi zifudumeza igumbi, zidinga izinkuni ezithile futhi nge-sauna ephumelelayo ikuvumela ukuba uhlele noma i-sauna, noma igumbi likamusi laseRussia. Kepha, ngeshwa, izimfanelo eza ngokuthengiswa zivame ukuhloselwe kuphela i-sauna, noma yokugeza yaseRussia, kodwa ngethangi elikhulu lamanzi. Lesi sihloko sichaza ukwakheka kwesakhiwo esizenziwe sosayizi omncane (Fig. 1), kulula ukukhiqiza futhi kubonakaliswa ukusebenza kahle. Ngokwenziwa kwayo, okusetshenziswayo okuguquke kabi, kwasetshenziswa izintambo zesondo kusuka emotweni yeZil-130. Banobubanzi obulungile (ukuphakama okungu-250 mm nobubanzi obungama-500 mm) nobukhulu obuhle - 7 mm.

Ingqikithi edingekayo izindondo ezine: ezimbili zazo - ngaphandle kwaphansi, kanti ezinye ezimbili zinediski ebekiwe enezimbobo. Ngaphezu kwalokho, sidinga amapayipi amabili ensimbi ngobude obungu-500-600 mm kanye nobukhulu bezindonga ze-5-6 mm, cishe izingcezu ezingama-60 zezitini, ukudideka kanye neminyango ye-cooker, i-valve.

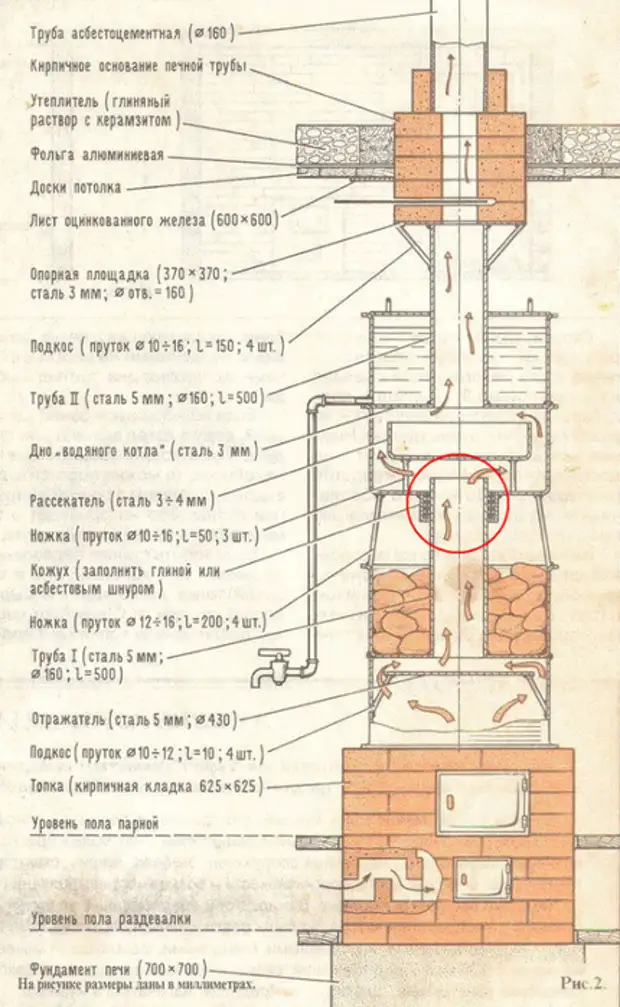

Ingxenye engezansi nephakathi yesithando somlilo, lapho izinga lokushisa liphezulu kakhulu, libekwe ngaphandle kwezitini ezibomvu ezishisiwe, eziqongelela ukushisa okwanele kokumiswa kokugeza. Ezitolovu zensimbi ezithengiwe ngeke uzithole. Ukufaka iminyango ye-flue kanye nokudideka kulo mklamo kulula kakhulu. Isithando somlilo sibekwe ebumbaneni e-polipich. Ubukhulu bayo bungama-625 x 625 mm.

Umklamo wama-rims amabili ufakwa esithandweni: ezansi - ngaphandle kwephansi, futhi phezulu - phansi ebheke esithandweni somlilo. Ama-rims afakwe komunye nomunye eceleni komphetho wangaphandle onomthungo oqinile.

Ku-Rod ephezulu (Fig. 2) enkabeni, ipayipi lifakwa, futhi izimbobo eziseceleni kwalo kanye nemifino yamuva zifakwa ngama-liners ensimbi anobukhulu obungu-5 mm. Emugqeni ophansi onezinduku zensimbi, i-selvector ye-welded - idiski yensimbi enobukhulu obungu-5 mm kanye nobubanzi be-120 mm ingaphansi kobubanzi be-rim uqobo lwabo uqobo. Kushintsha ukuqondiswa kokuhamba kwamagesi, okwandisa ukubuya kokushisa kwe-rim mina kanye ngaphansi kwesigaxa lapho amatshe abekwa khona. Isibonisi siyasiza ukwenza ikhonsani.

URim III nge-divider ukhonza ngokudluliswa okungeziwe kokushisa. Igcina izinduku ezine, ifakwe ezungeze umngcele ongaphansi futhi iphumule eRim II. Zonke izimbobo ze-RIM III, ngaphandle kweCentral, zifakwe ngama-liners ngobukhulu obungu-4 mm, futhi phakathi, ukubambana nobubanzi bamasentimitha ayi-10-30 mkhulu kunobubanzi bepayipi. Lapho ukuhlangana, lesi sikhala sasigcwele intambo ye-asbestos (ungagcwalisa ubumba).

Ukwahlukanisa (bheka i-Fig. 2) yenziwe ngensimbi engu-4-mm. Igebe phakathi kwe-divider ne-rim ngu-30- 40 mm. URim IV yi-boiler yokushisa kwamanzi. Ukuhlelwa okunjalo kokubili kwe-boiler ne-heater kukuvumela ukuthi ukhethe ngempumelelo ukushisa kusuka ekudlule kudlule amagesi ashisayo engxenyeni ephakathi yesithando somlilo futhi, ngaphezu kwalokho, ukuthola amanzi ashisayo. Amandla we-boiler - amalitha angama-40. Lokhu kwanele kubantu abahlanu kuya kwabayisithupha.

Phansi kwe-boiler - kusuka ku-4-mm Steel. Maphakathi nendawo, umgodi futhi ushaye phansi ngepayipi elinqunyelwe, kuya phezulu lapho ipulatifomu yensimbi ifakwe ngaphansi kwesisekelo sezitini ze-chimney. Lapho uqoqa i-boiler yafakwa kuRim III ngokusebenzisa i-lining kusuka ku-asbestos intambo ngodaka. Ezansi kwe-boiler ifake ishubhu nge-crane ngezansi. Phezulu kwe-boiler kuvalwe ngesembozo esikhiphekayo esihlanganisa ama-duralum amabili uhhafu wobukhulu obungu-2 mm.

I-valve epayipini ifakwa ngemuva kokubeka ubumba bomugqa wokuqala wezitini. Ipayipi - isigaba sesikwele, ububanzi bezitini bukahhafu. Lo mklamo uhlinzeka ngokuphepha komlilo othembekile futhi wenza lula ukufakwa kwe-valve. Ngaphezulu kweshubhu le-ATTIC Smoke yenziwa ngesidina esibikwe ngodonga olubi kakhulu. I-160 mm. Kumele kwaziwe ukuthi isisindo seshubhu lentuthu akufanele sidlule ku-50 kg, njengoba sincike phansi kwe-boiler.

Isithando somlilo singenziwa kunoma yimuphi umhlangano lapho kukhona khona i-welding kagesi. Idizayini ingaqoqwa kusuka ezingxenyeni ezithile ezizimele, okulula ukuletha endaweni yokufaka esiqwini semoto yabagibeli. Enye yezinketho zokufaka isithando somlilo esinjalo futhi kukhonjisiwe ku-Fig. 2.

Udonga oluhlukanisa igumbi leSteam kusuka egumbini lokukhiya lidlula esitofini futhi ukuphepha kwenziwa ngezitini (Fig. 3). Indlela eya eMnyango Wezinsana kanye nophethiloli isuka egumbini lokukhiya, elilungele kakhulu. Ingxenye engezansi ye-ASH Bar iza ngaphansi kwebhodi lebhodi eliphansi ngokusebenzisa umgodi we-60x130 mm ngosayizi, oqinisekisa umoya omncane wesampula. I-Rim engezansi ngesikhathi somlilo ifudunyezwa yi-Hot. Ukuze ungashisi, ama-rims I no-II, ngabeka izitini ezinhlangothini ezintathu, ngibeka umyalo wazo we-chess. Udonga lwepulangwe lokugeza, oluseduze kwesitofu, luvikelwe yizitini ezibekwe emaphethelweni ziye ezansi kwe-rim yesithathu.

Uma usebenzisa ukugeza njenge-sauna, amanzi e-boiler akufanele athelwe, futhi uma amanzi ashisayo esadingeka, khona-ke ungabeka amabhakede amabili amanzi eduze kwehhavini enodonga lwangaphandle. Lokhu ngeke kuholele ekukhuphukeni okubonakalayo komswakama.

Uma ugoba i-birch ye-birch eyomile (nge-ridbox enhle nebhokisi lomlilo eliphakeme, zombili izinkuni zomlilo ezivundwayo zivutha kalula), bese kuthi ku-0 ° C ngaphandle kwehora ngemuva kokuqala kwesithando, izinga lokushisa e-sauna lifinyelela ku-120 ° C. Ukugcina le modi, kwanele ukwenza i-3-4 evuthayo. Uma izinkuni zingezinhle, ngemuva kokuthi izinga lokushisa lizowa, futhi ungadlula emfushane, ushiye amanzi ngamatshe ashisayo. Uma nje udinga ukugeza, ungathela amanzi ku-boiler, 40 l, okufuthelwe isigamu sehora kuya ku-60-70 ° C.

Ukugeza okunesithando esinjalo okwenziwe ngumlobi kusetshenziswa iminyaka emithathu. Lo mklamo waphumelela - vele omakhelwane abambalwa abazakhela njengale.