In the presence of desire and standard tools, any owner has the ability to make useful things for their home on their own.

It is to such a necessary subject of furniture in the hallway a bench, inside which you can store shoes, and making it also soft, you can ensure comfort along with additional convenience.

The problem with the placement of a large number of shoes and boots is relevant in almost every home.

The advantage of the manufacture of such a bench independently, it is also possible to choose the size necessary for its hallway, as well as the materials you like, the appearance specifically to your needs and taste.

Consider the easiest option, shops from the boards with their own hands.

To do this, you will need:

First of all, a standard tool kit: Roulette;

saw, screwdriver;

Bulgarian;

screwdriver;

drill;

sandpaper;

Slicer for stripping.

And secondly, such a material: a ram for the frame 4 * 3cm;

Rake 4 * 2cm;

Rake horizontal side 2pcs, length 87cm;

Rake horizontal transverse, length 19.5cm;

Bar for legs 4pcs, 42cm;

Morilka, PVA glue;

14 tie screws;

Olife or varnish.

To enhance the design additionally: one horizontal rail 870mm long;

two transverse 195mm;

as well as 2 shelves.

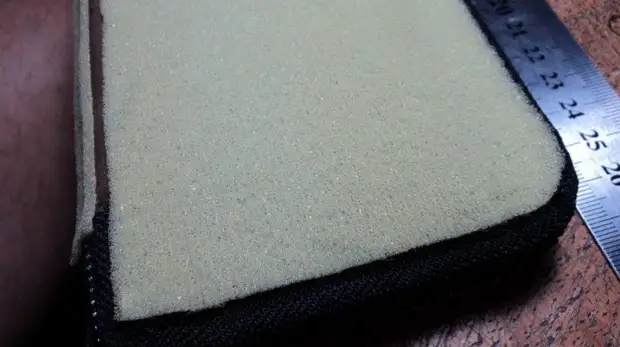

For soft seats will need:

Plywood thickness is at least 1cm, size 950 * 250mm;

leatherette;

Foam rubber (8 identical parts, size of 2000 * 100mm).

The process of macass manufacturing

Cutting off all parts according to the set size, it is necessary to get rid of wood irregularities (scratches, dirt) with a rough skin or sandpaper. The following action will collect the frame of the bench.

Connections are made, not using corners or grooves;

The parts are applied to each other according to plan, the drill is made with a 4mm diameter;

It is important that the hole is in both details.

The hole in which the screw base will be required to additionally drill a 6mm diameter drill, so that the screw does not deform the edge of the part;

In the second hole, where the second part of the screw will be, it is required to cut a thread in advance;

If in other places the connections will not be enough of the length of the screw, you can drill its head deep to 1 cm.

With these tips, the basis is going to:

Frame, legs, strengthening of two plates.

Next you need to prepare 2 shelves. Mark their uniform location and blank a hole for strengthening.

The next step will be the disclaimer of the harvested structure in order to glue it with PVA glue for better strengthening.

The glue is applied to the joint;

It is required to wait a few minutes to ensure that it is;

joints are tightly strengthened by tightening screws;

Luxurious glue out, you need to immediately wipe it with a dry cloth.

The finished frame is covered first in several layers of the veil, and after varnish or oil.

The penultimate action remains a comfortable seat for the resulting bench.

To collect, lay out on the floor layers:

leatherette;

8 pieces of porpoil;

plywood sheet;

Next, everything is wrapped by dermatin from the wrong side and is attached by self-drawing;

Excess parts are cut off.

It remains only to strengthen the seats with the ready-made framework. According to approximate calculations, such a bench goes several times cheaper than the store. It will certainly please the whole family with its convenience and an attractive appearance.